Side-Gusseted Bags

Contact

| Functionality: | Side-gusseted bags are plastic bags with expandable pleats on both sides, allowing them to hold more items than traditional flat plastic bags while helping the bag maintain its original shape. |

| Material: | PP, LDPE, HDPE |

| Size: | Various, customizable to customer requirements. |

| Thickness: | Options from 20 to 160 microns. |

| Color: | Clear, opaque white, black, blue, red, and other colors as requested. |

| Features: | Durable, waterproof, and resistant to both high and low temperatures. |

| Packaging: | Custom packaging available upon customer request. |

- Description

Description

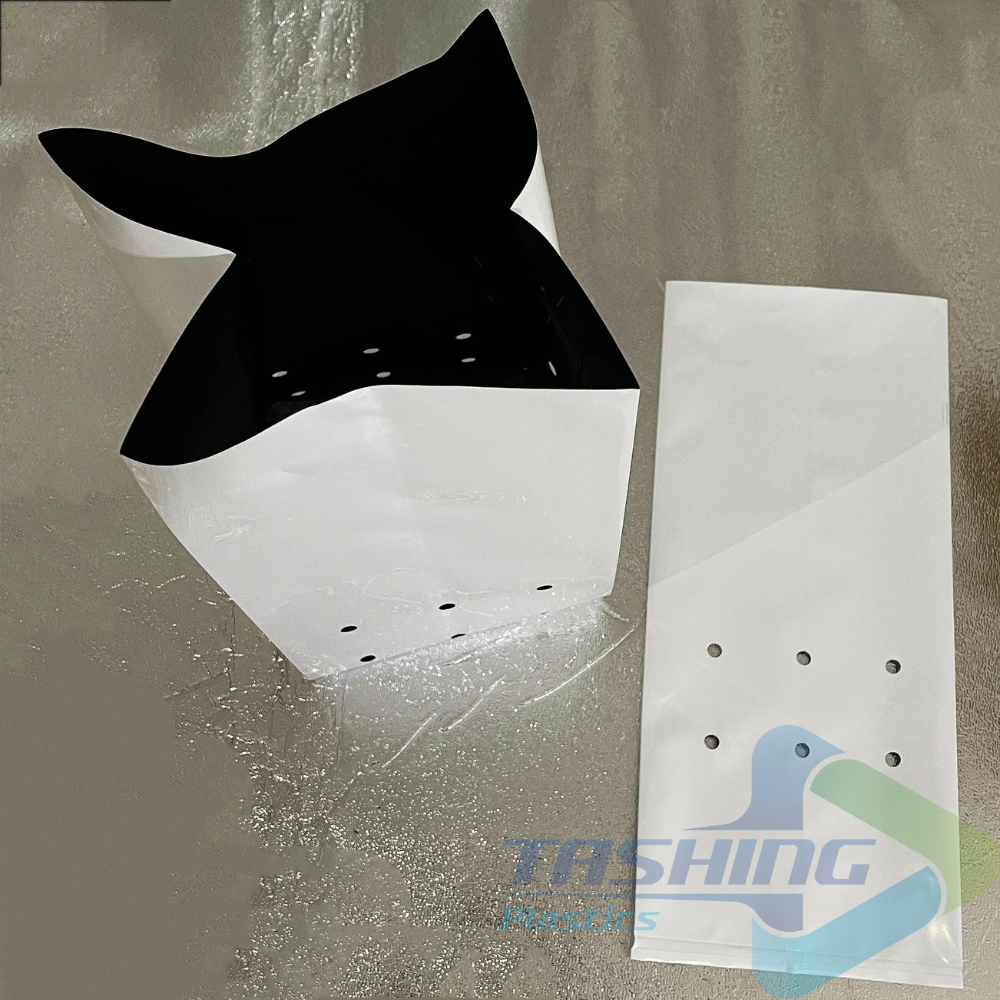

A side-gusseted bag is a type of plastic bag with expandable pleats on both sides. These pleats stay close to the sides of the bag until it is filled, at which point they expand to hold the items inside. These pleats, known as side gussets, allow the bag to hold more items compared to traditional flat plastic bags while helping the bag maintain its intended shape.

Advantages of Side-Gusseted Bags:

- Enhanced Capacity: The gussets allow the bag to expand horizontally, enabling it to hold more items than a regular plastic bag.

- Easy to Pack and Use: The side gussets make packing and removing items from the bag easier.

- Space Saving: When organized, gusseted bags take up less space compared to traditional plastic bags, saving storage space.

- Convenient to Carry: Thanks to their compact and foldable design, side-gusseted bags are convenient for travel, business trips, or shopping.

- Product Protection: Side-gusseted bags protect the items inside from environmental factors such as dust, moisture, and impact.

- Cost Savings: Compared to other packaging types, side-gusseted bags typically have lower production costs.

- Improved Aesthetic Appeal: Side-gusseted bags can be designed with various colors and patterns, enhancing the appeal of the packaged products.

- Easy to Transport and Store: Side-gusseted bags can be stacked neatly, saving warehouse space and reducing transportation costs.

Applications of Side-Gusseted Bags:

- Packing food items like bread, cookies, and candy

- Packing household items like nails, screws, and bolts

- Packing clothing such as T-shirts and socks

- Packing household items like pillows and blankets

- Packing electronic devices like cables and chargers

Side-Gusseting Process

To create the side gusset of a plastic bag, after the bubble is blown to the desired size, the tube roll passes through two pressure bars that press the PE bubble inward to a certain point, adjusting it to the appropriate size. The film is then pulled and rolled up, which pushes the air to the back, and the gusset is fixed on the film roll.

Steps to Create the Gusset for Plastic Bags:

- Blow Air into the Bubble

- The PE resin, after being heated and pressed through the extruder, is injected with a certain amount of air to create the PE bubble.

- The size of the bubble is adjusted to the final desired size of the plastic bag.

- Press to Create the Gusset

- The plastic bubble passes through two parallel pressure bars.

- The pressure from the bars causes the bubble to indent, forming two folds (the gusset) along the bubble’s length.

- The depth of the gusset is adjusted by changing the distance between the two pressure bars.

- Stretch and Roll

- After creating the gusset, the plastic bubble continues to be stretched and rolled up.

- This process pushes air out from inside the bubble and secures the gusset around the spool.

- Finished Product

- After completing this process, the roll is cut into individual gusseted bags.

Side-Gusseted Bag Manufacturer – Di Dai Hung Co., Ltd. (Tashing Plastics Co., Ltd.)

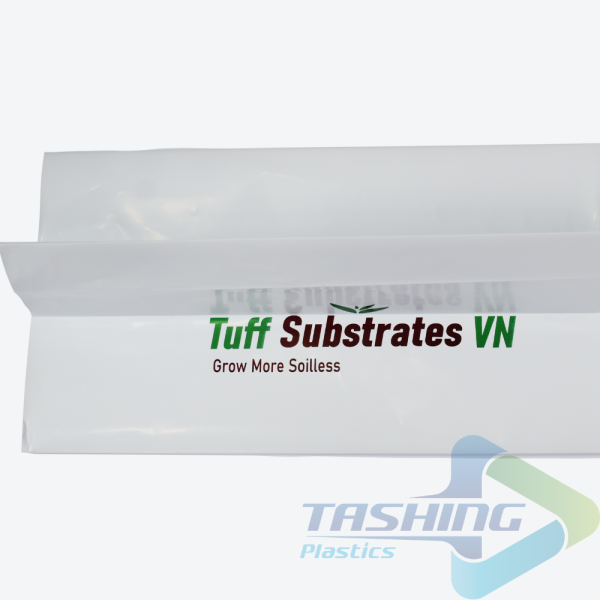

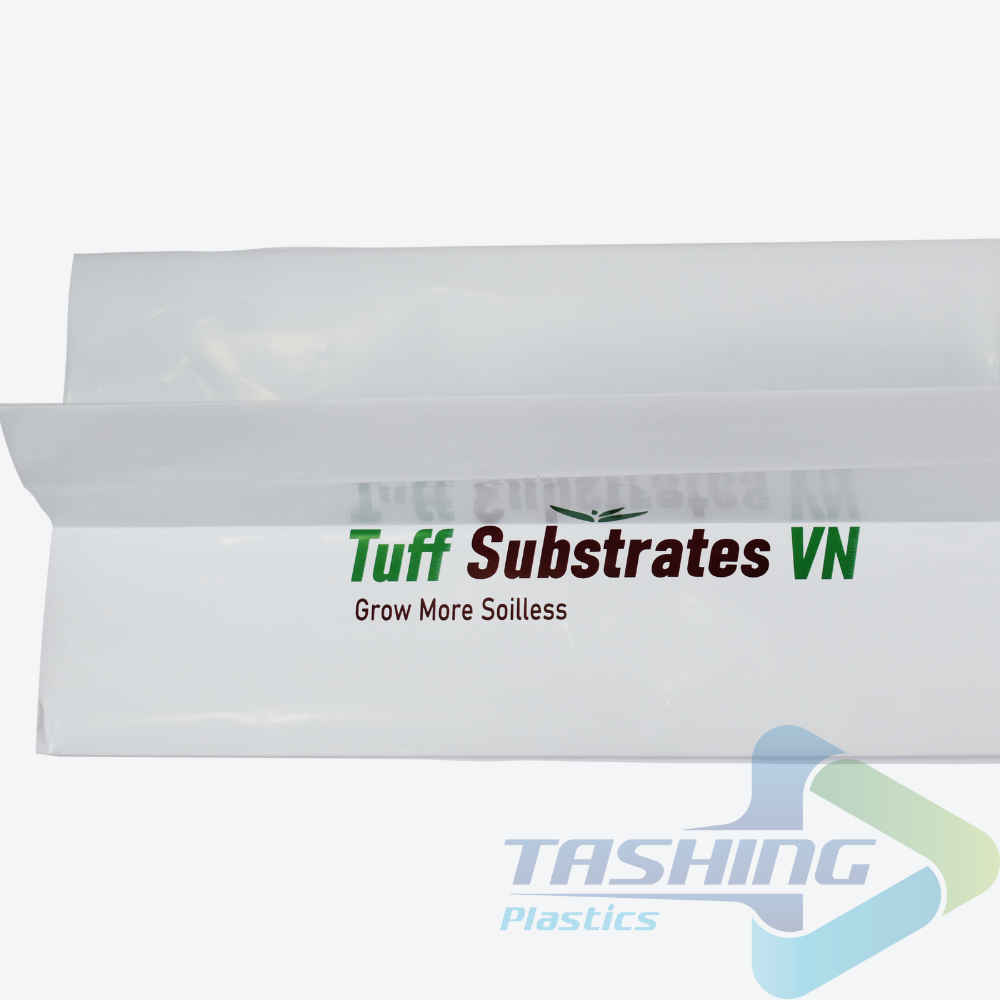

With over 40 years of experience in packaging production, Tashing is proud to be a trusted partner for businesses of all sizes. We offer a wide variety of side-gusseted bags, including PE, PP, transparent, and custom-printed bags. Tashing’s side-gusseted bags are not only durable and attractive but also help businesses save costs and enhance brand image.

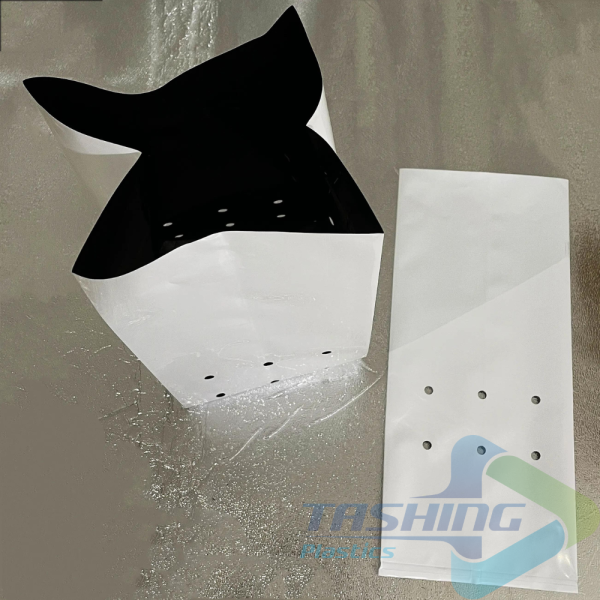

Types of Side-Gusseted Bags Produced by Tashing:

- PE Side-Gusseted Bags: Made from Polyethylene, ensuring high durability and flexibility.

- PP Side-Gusseted Bags: Made from Polypropylene, providing stiffness and good load capacity.

- Transparent Side-Gusseted Bags: Designed with transparency, allowing the contents to be visible, suitable for multiple purposes.

- Printed Side-Gusseted Bags: Designed with attractive printed patterns, ideal for packaging products that require visual appeal and brand promotion.

Tashing is committed to delivering high-quality products that meet the diverse needs of our customers while contributing to environmental protection. We believe that through continuous effort, Tashing will remain a trusted partner in the flexible packaging and plastic products industry. Contact us today for consultation and orders