About us

ABOUT US

Di Dai Hung Co., Ltd (Tashing plastics Co., Ltd) was originally established from a small enterprise specializing in manufacturing flexible packaging & plastic products since the 1980s, when the plastics industry started to become popular in Vietnam. Over the past 30 years, Tashing has grown progressively, and become well-known as a trusted supplier of flexible packaging & plastic products to domestic & international clients.

Tashing always focuses on improving the quality of human resources, investing in machinery & equipment, updating new technology. Our production and operation are continuously improved based on ISO 9001:2015 Quality Management System (QMS). Tashing has made a difference from product quality to leading service standards, to fullfil all specific clients’ needs.

Tashing provides reliable products & services to clients from several sectors including retail shops; supermarkets nationwide; manufacturers of equipment, electronic devices, consumer goods, garments, food; companies operating in agriculture-forestry-fisheries, advertising agency, etc. Aiming for the highest customer satisfaction, we strive to provide an excellent service in terms of quality of work, timely delivery, professional behaviour, customer service and value for money.

As our slogan goes “Work together – Grow together”, we welcome all strategic cooperation from valued partners and clients at both domestic and international levels.

For the Environment:

Minimize impact on the environment and promote sustainability. We are committed to using environmentally friendly materials and manufacturing processes to reduce waste, conserve resources and protect the planet for future generations.

For customers:

Providing customers with high quality specialized plastic products and always meeting customer expectations.

For Businesses:

Building a safe and positive working environment that promotes individual development and happiness, Encouraging employees to actively participate in sustainable development efforts, creating a culture of responsibility to society and community.

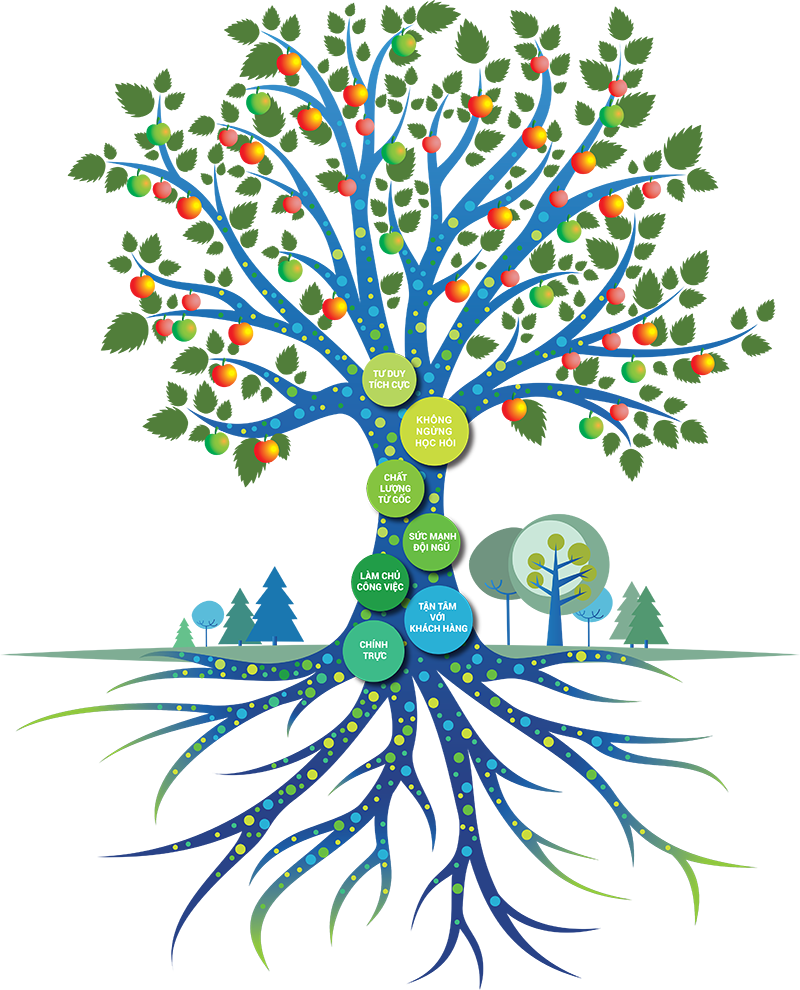

CORE VALUES

- Integrity

- Dedication to customers

- Job ownership

- The power of teamwork

- Quality at the source

- Continuous learning and creativity

- Positive Thinking

PRODUCT

Flexibel plastic packaging:

PP, LLDPE, LDPE, HDPE, OPP, BOPP, PA/PE in different shapes such as: Film, Sheet, Roll, Bags on roll, Die-cut bag, T-shirt bag,etc.

Our main products are: nursery plastic bags, mushroom embryo bags, PE bags for food & non-food packaging, bags for furniture/machine covers, bags for metal, electronic components packaging, agricultural film, watering plastic tube, PE shrink film, zipper bags, garbage bags, bio-degradable garbage bags, friendly environmental plastic bags, anti-static plastics bags, pallete cover bags, etc….. with many different styles & sizes to accommodate variety of application.

Plastic product

- Plastic products PP, ABS, PS, SAN, HIPS, HDPE, PA, …

- Household plastic products (such as tool boxes, multi-purpose bins, food containers, flower pots, Plastic basket set, etc.)

- Industrial plastic products (such as Plastic drums, plastic components, plastic trays, etc.)

- Consulting and processing specialized plastic products according to customer requirements

PRODUCTION CAPACITY

COMMITMENT TO THE ENVIRONMENT

Environmental protection is a top priority at Tashing. Being a plastic manufacturing business, we fully understand the potential environmental impact of our production activities. We are dedicated to minimizing this impact and promoting sustainable practices throughout our operations. Thus, Tashing has implemented a comprehensive environmental management system to reduce environmental harm. Our environmental policy focuses on key elements: reducing, reusing, recycling, and responsibly disposing of materials.

To minimize our environmental footprint, we prioritize the use of sustainable materials in our manufacturing process. We have established recycling programs across our facilities to decrease the amount of waste generated. Our factory staff undergo training to effectively sort and process waste, ensuring it is either recycled or disposed of responsibly.

Furthermore, we recognize the importance of environmental education and awareness in safeguarding the natural environment. In recent years, we have introduced products made from environmentally friendly materials to contribute to environmental preservation in a more sustainable manner.