OPP Bags

Contact

| Feature | Details |

|---|---|

| Function | Used for packaging food, gifts, components, apparel products, etc., helping to keep items clean and enhance aesthetic appeal. |

| Material | OPP (Oriented Polypropylene) plastic, transparent with a glossy finish. |

| Size | Various sizes, depending on the specific needs. |

| Thickness | Typically ranges from 20 to 60 microns. |

| Color | Transparent or custom-printed with designs or logos as required. |

| Features | Glossy surface, excellent moisture resistance, easy to heat seal or adhesive seal. |

| Packaging | Customized as per requirements. |

- Description

Description

OPP Bag (Oriented Polypropylene) is a type of plastic bag made from oriented polypropylene material, known for its high transparency, glossy surface, and good durability. OPP bags are commonly used for packaging food, clothing, stationery, and other products due to their moisture resistance, safety for health, and excellent visual appeal. Notably, they can be designed with air holes or self-adhesive seals, making them suitable for both storage and product display.

Properties of OPP Bags

OPP (Oriented Polypropylene) bags stand out thanks to their distinctive physical and chemical properties, making them suitable for various industries such as food, fashion, and stationery. These characteristics not only ensure product protection but also enhance aesthetics and usage efficiency.

|

|

1. Physical Properties

| Property | Value |

|---|---|

| Density | ~0.90 g/cm³ |

| Thickness | 12 – 50 microns |

| Tensile strength | 200 – 300 MPa (in both machine and transverse directions) |

| Elongation at break | 50 – 150% |

| Transparency | > 90% |

| Haze | < 5% |

| Melting point | 160 – 180°C |

| Heat resistance | Up to 150°C |

2. Chemical Properties

| Property | Description |

|---|---|

| Main component | Oriented polypropylene |

| Chemical resistance | Resistant to acids, bases, and many common solvents |

| Toxicity | Non-toxic, odorless, safe for food contact |

| Flammability | Flammable, with a limited oxygen index of about 17–18% |

| Thermal stability | Poor stability above 200°C (begins to decompose) |

| UV resistance | Degrades under UV light without stabilizers |

Advantages and Disadvantages of OPP Bags

Advantages of OPP Bags

OPP (Oriented Polypropylene) bags offer many outstanding advantages, particularly their high transparency, which allows the contents to be clearly visible. This makes them ideal for display packaging such as food, confectionery, and stationery. The bag’s glossy, smooth surface not only adds a touch of elegance but also enhances the product’s visual appeal, increasing its perceived value.

Thanks to the stretching process during production, OPP bags have excellent mechanical strength, making them resistant to tearing and punctures in the oriented direction.

Additionally, the material’s natural water-repellent properties provide effective moisture resistance, protecting products from humid environments. OPP bags also exhibit high chemical stability, offering good resistance to most acids, bases, and common organic solvents, which helps maintain product quality under various storage conditions.

|

|

|

Disadvantages of OPP Bags

Despite their outstanding advantages, OPP bags do have certain limitations. While they offer good tensile strength in the oriented direction, they tend to become brittle and may crack when subjected to force perpendicular to the orientation. This makes them less flexible for packaging products that require high elasticity or are exposed to frequent impacts.

Therefore, when using OPP bags for products that demand strong impact resistance, it is important to consider appropriate reinforcement measures to ensure the durability and quality of the packaging.

How OPP Bags Are Made: Production Process

The production of OPP (Oriented Polypropylene) bags involves multiple stages, from raw material preparation and film extrusion to final bag conversion. Each step plays a crucial role in ensuring the finished bags meet standards for mechanical strength, aesthetic appeal, and product protection. Below are the basic steps in the OPP bag manufacturing process:

Step 1: Raw Material Preparation

The process begins with polypropylene resin, usually in the form of small pellets or granules. These are produced by polymerizing propylene gas with a catalyst (typically a Ziegler-Natta catalyst) in a controlled industrial setting. The polypropylene resin is then transported to OPP bag manufacturing facilities as ready-to-use raw material. Before processing, the resin is melted and purified to remove impurities and ensure product quality.

Step 2: Film Extrusion

The molten polypropylene is fed into an extruder—a machine that pushes the plastic through a narrow die to form a continuous flat sheet. This sheet is quickly cooled using chilled rollers, solidifying it into a thin, unoriented film. At this stage, the film is still opaque and relatively weak.

Step 3: Orientation (Stretching)

Orientation is the most critical stage. The unoriented film is reheated to just below its melting point (around 130–150°C) and passed through a series of rollers. These rollers stretch the film in the machine direction (lengthwise), typically 4 to 8 times its original length. This stretching aligns the polymer molecules, transforming the film into transparent, strong, and glossy OPP film. The film thickness usually ranges from 20 to 50 microns, depending on the intended application.

Step 4: Cooling and Stabilization

After stretching, the film is cooled again to “lock in” its new molecular structure. This step helps the film maintain its enhanced properties. Some manufacturers may also apply surface treatments, such as corona discharge, to improve printability and the adhesion of labels or heat seals.

Step 5: Bag Conversion

The OPP film is then cut, folded, and sealed into bags. This process may include:

- Heat sealing: Using heated bars to bond the bag edges, creating airtight, strong seals.

- Adhesive strips: Adding resealable tape for bags that can be opened and closed multiple times.

- Perforation: Creating tear lines or ventilation holes (e.g., for fresh produce bags).

- Printing: Applying logos, designs, or product information using flexographic or rotogravure printing techniques.

The final result is a fully formed OPP bag, ready for packaging everything from snacks to garments. The production process is highly automated, enabling manufacturers to produce thousands of bags per hour at a low cost.

|

|

Comparison of OPP Bags and Other Types of Plastic Bags

OPP bags are favored in the plastic packaging industry thanks to their high transparency and glossy surface, which enhance product visibility and appeal. To choose the right type of bag, it’s important to consider durability, aesthetics, and intended use. The following table compares OPP bags with other common types of plastic bags to help you make an informed decision.

| Bag Type | Advantages | Disadvantages | Applications |

|---|---|---|---|

| OPP Bag | High transparency and glossy finish, enhances product presentation. | Easily tears at the edges under strong impact. | Packaging for dry food, confectionery, stationery, clothing, garments, and display items. |

| PP Bag | Flexible, durable, more tear-resistant than OPP bags. | Lower transparency compared to OPP bags. | Packaging for food, electronic components, medical tools, and general goods. |

| LDPE Bag | Soft, highly flexible, good elasticity. | Low transparency, matte surface. | Used for frozen food, supermarket bags, liquid containers, and soft trash bags. |

| HDPE Bag | More rigid than LDPE, good load-bearing capacity. | Rough surface, not glossy or smooth. | Supermarket bags, trash bags, food packaging, and heavy-duty bags. |

| PVC Bag | Tough, durable, withstands high impact. | Prone to yellowing or hardening over time. | Packaging for cosmetics, food, plastic cards, product covers, toys, and fashion items. |

OPP bags stand out for their high transparency and glossy surface, making them ideal for products that need an attractive display, such as dry food, sweets, and clothing. Compared to PP bags, OPP bags are less durable and more prone to tearing but offer superior visual appeal. While OPP bags are not as flexible or impact-resistant as LDPE and HDPE bags, their shiny surface makes products more visually appealing. Although PVC bags offer the highest durability, they tend to yellow or harden over time, whereas OPP bags maintain their sleek look longer. Therefore, OPP bags are a suitable choice for products where aesthetics are a priority.

Applications of OPP Bags

Thanks to their high transparency and glossy surface, OPP bags are widely used across various industries, especially for products that require a high level of aesthetic appeal.

-

Packaging for Dry Food

OPP bags are an ideal choice for packaging dry food items such as candies, cashew nuts, peanuts, and dried fruits. Their high transparency allows customers to clearly see the product inside, while the shiny surface gives a clean and attractive look, enhancing the perceived value of the product.

|

|

-

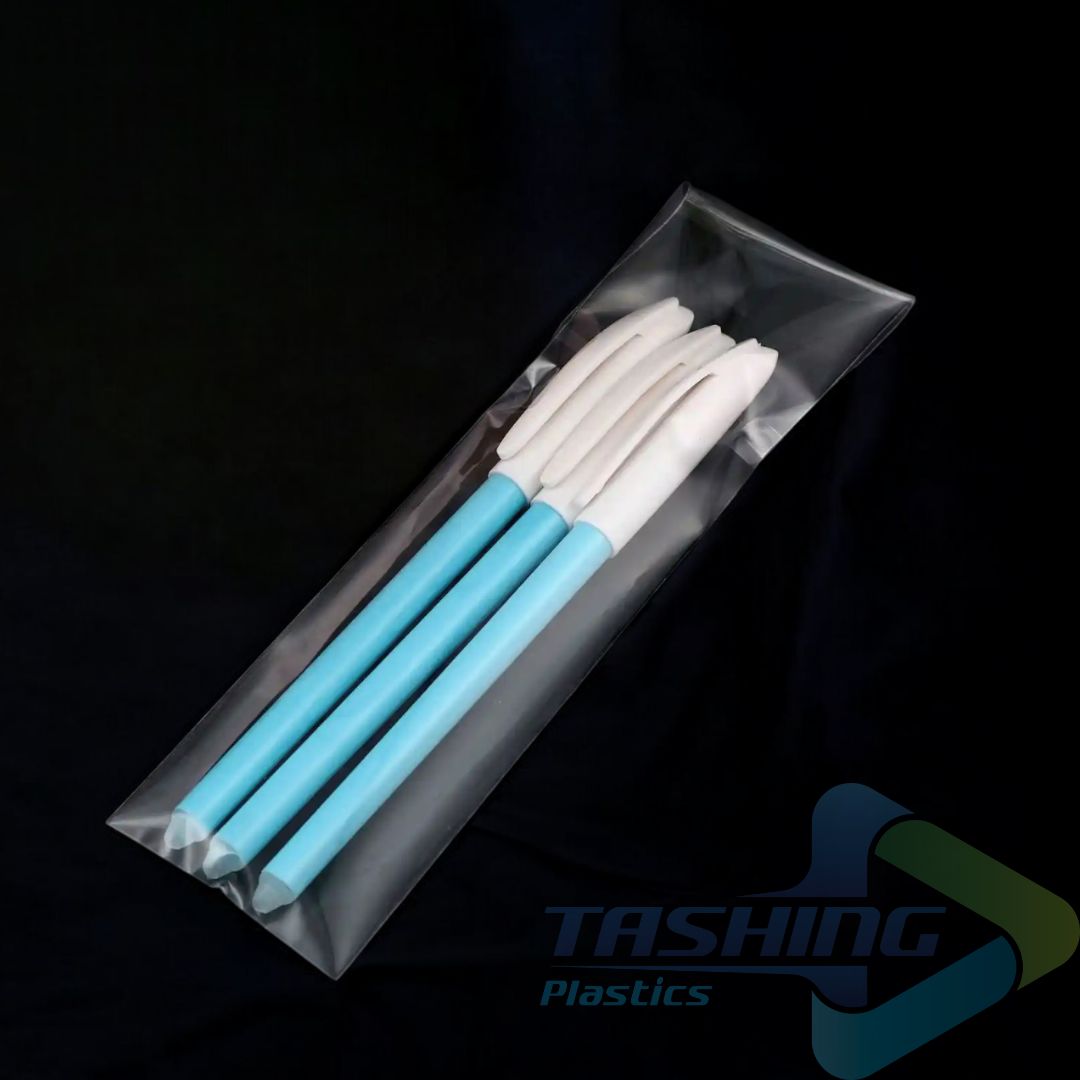

Stationery Packaging

Stationery items such as pens, rulers, notebooks, and invitation cards are often packaged in OPP bags to protect them from dust and scratches. OPP bags not only help maintain the product’s quality but also create a professional and polished appearance when displayed.

|

|

-

Clothing and Garment Packaging

In the fashion industry, OPP bags are a popular solution for packaging items such as T-shirts, scarves, and underwear. Their high transparency enhances the visual appeal of the products and allows customers to easily see the color and fabric texture without needing to open the bag.

|

|

-

Packaging for Printed Materials and Promotional Items

OPP bags are used to protect printed materials such as calendars, posters, catalogs, and promotional items. Their glossy finish enhances the visibility and attractiveness of the products, while their dust-resistant properties help keep items clean and presentable during display or transportation.

-

Gift and Souvenir Packaging

With their sleek and elegant appearance, OPP bags are a great choice for packaging small gifts, souvenirs, or handmade crafts. These bags add a touch of sophistication and help make the gift more visually appealing and memorable.

|

|

-

Applications in Agriculture

In agriculture, OPP bags are used for packaging seeds, organic fertilizers, dried agricultural products, and fresh vegetables. Additionally, OPP bags are used to package fresh flowers due to their high transparency, which enhances the beauty of flower bouquets during display. The glossy surface and dust-resistant properties help keep the flowers clean, giving them a more luxurious and refined look when used for decoration or as gifts.

|

|

Common Types of OPP Bags

-

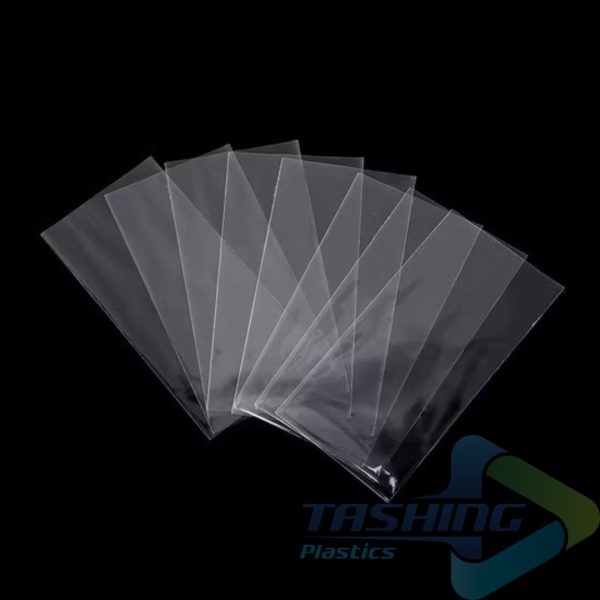

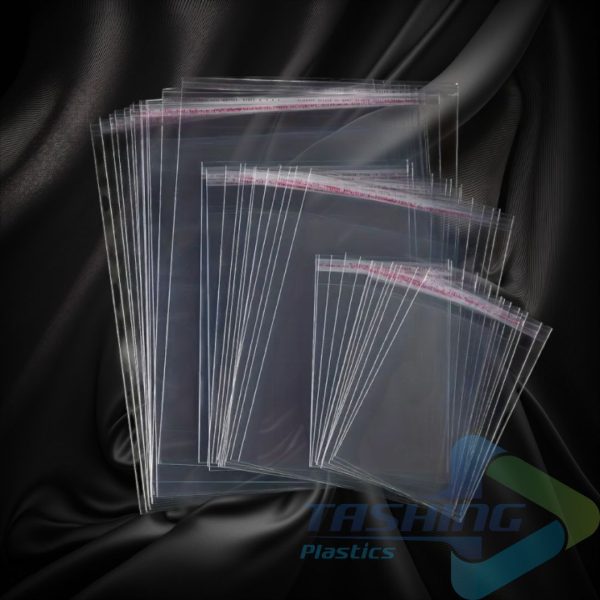

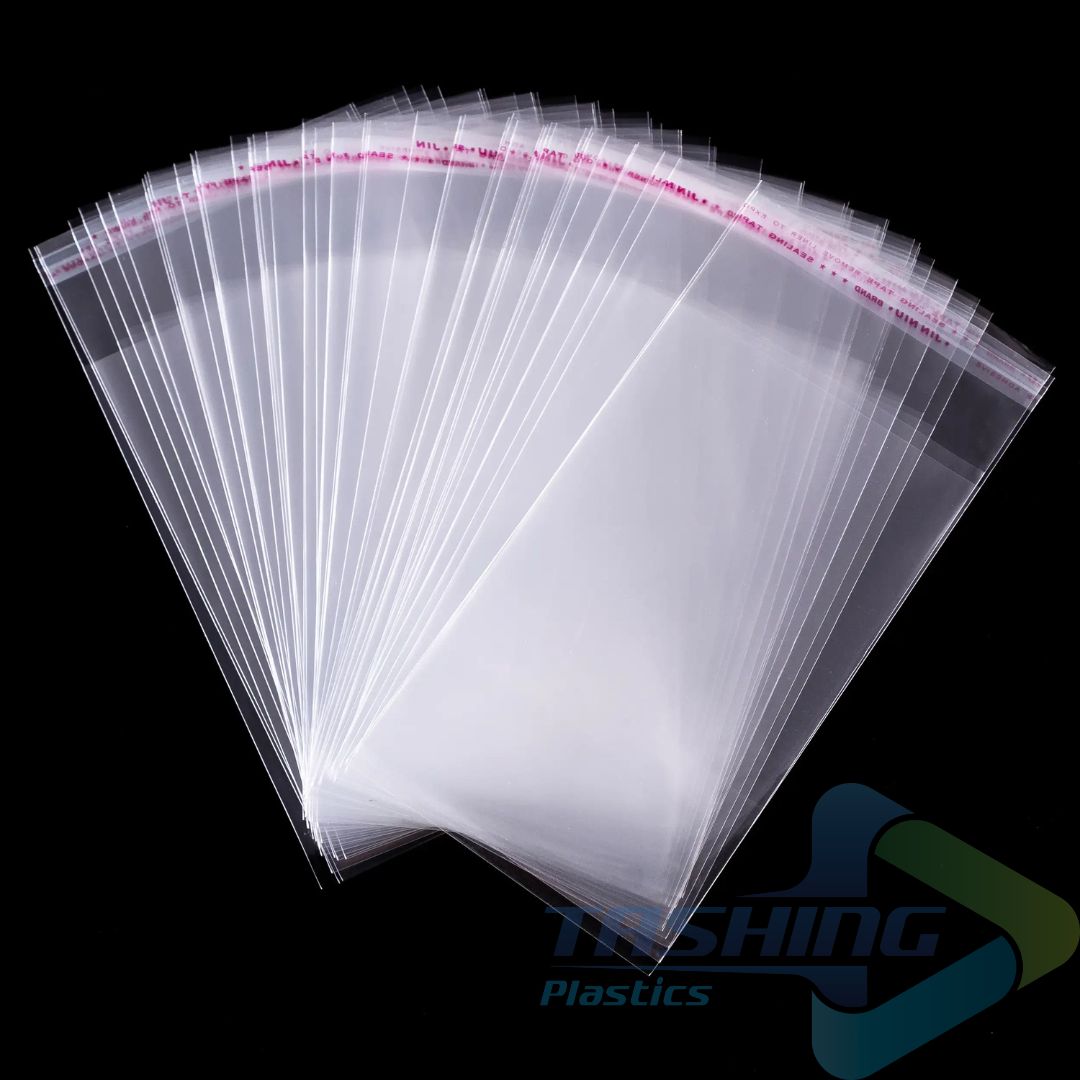

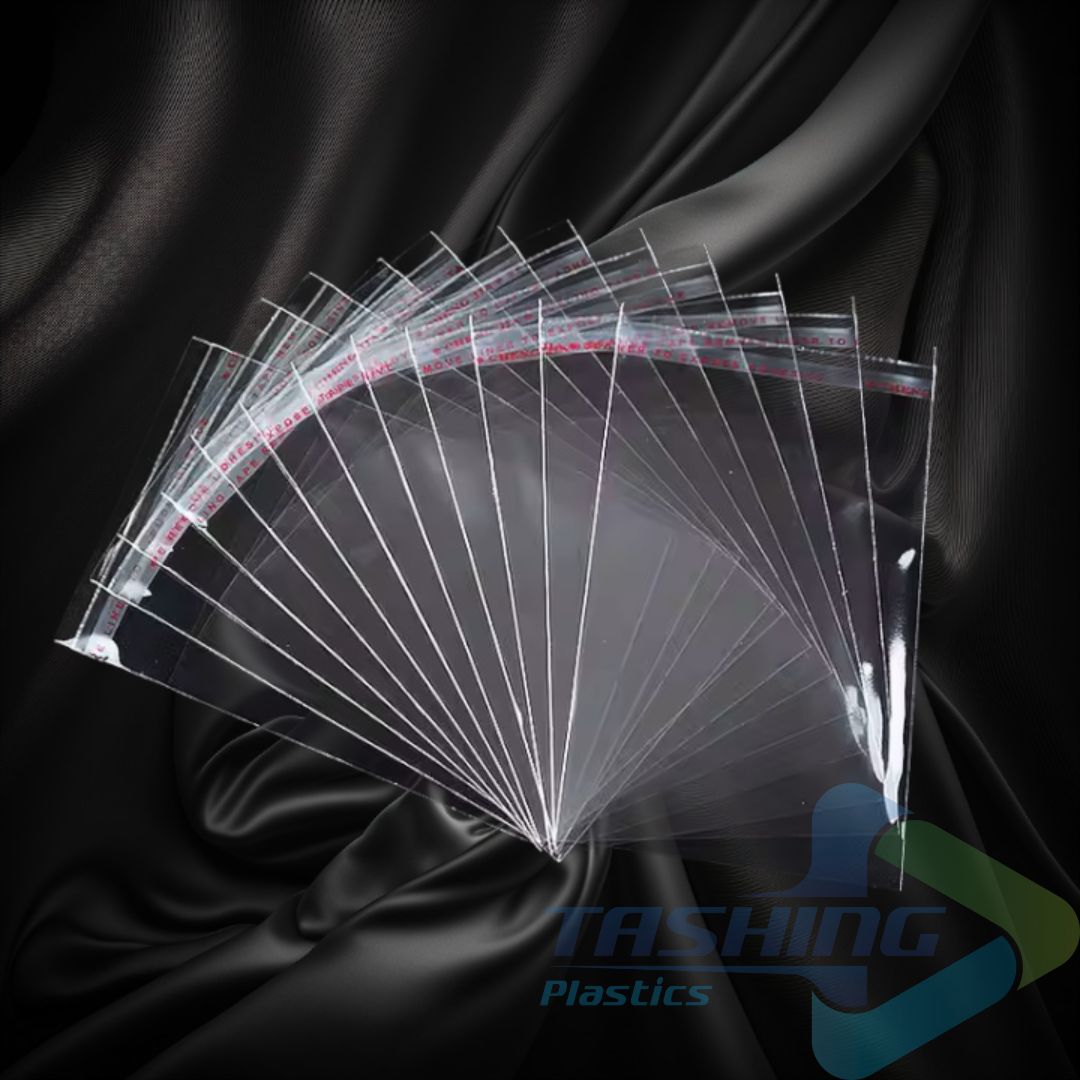

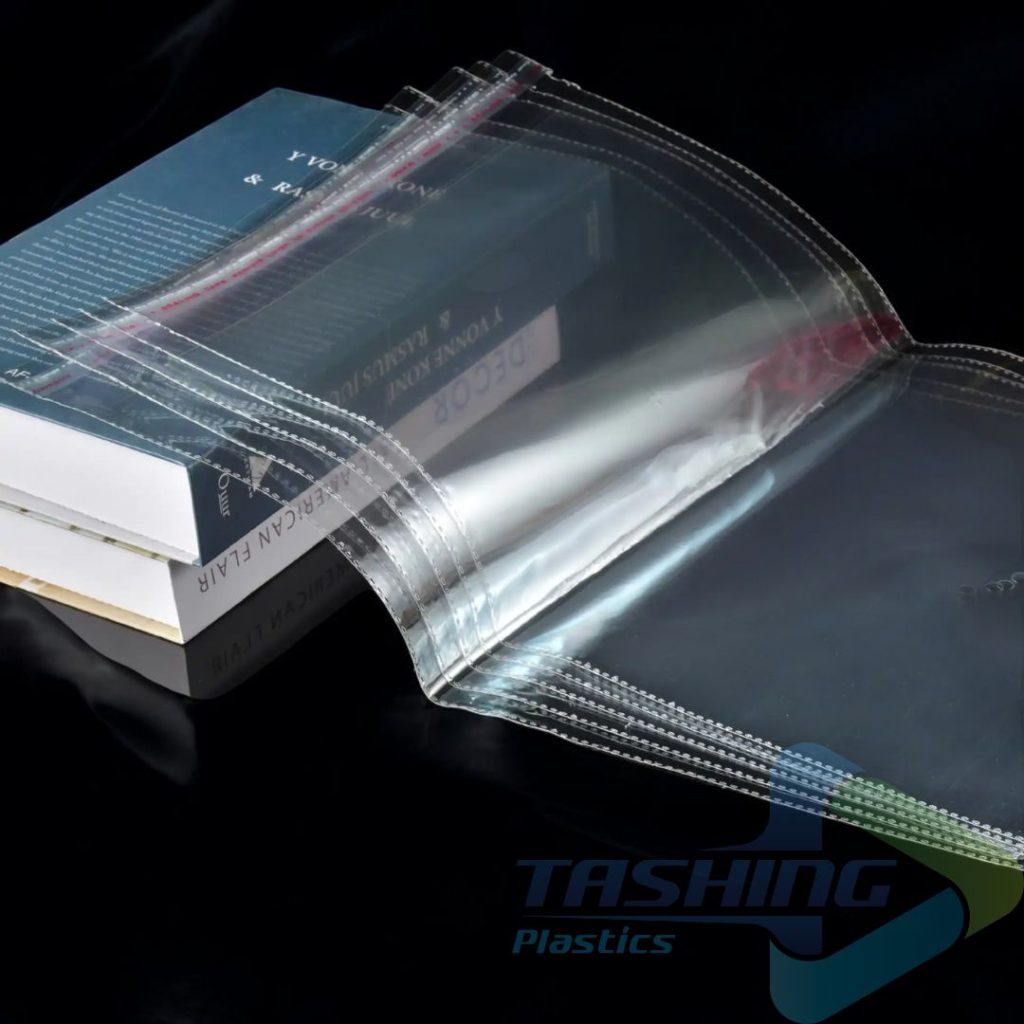

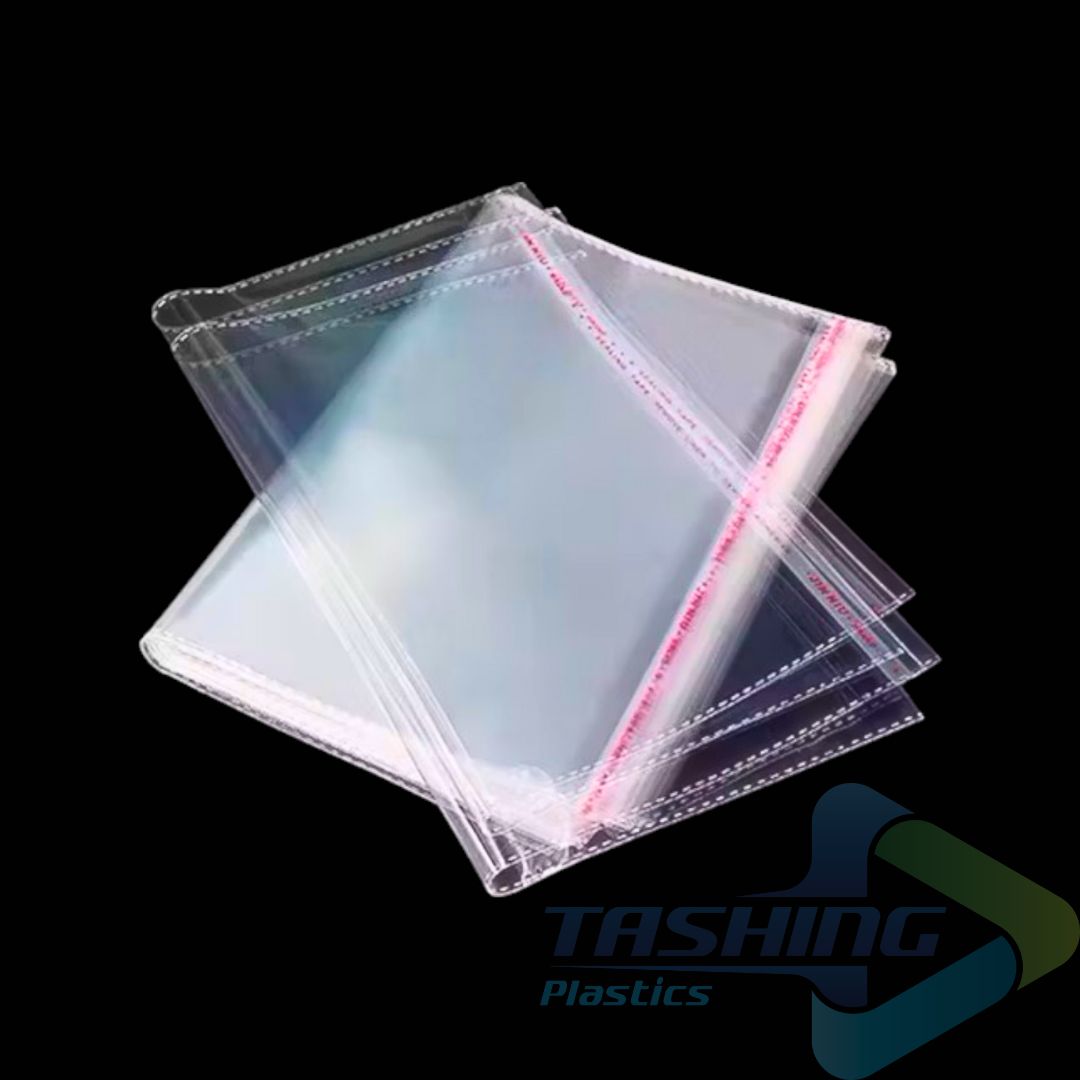

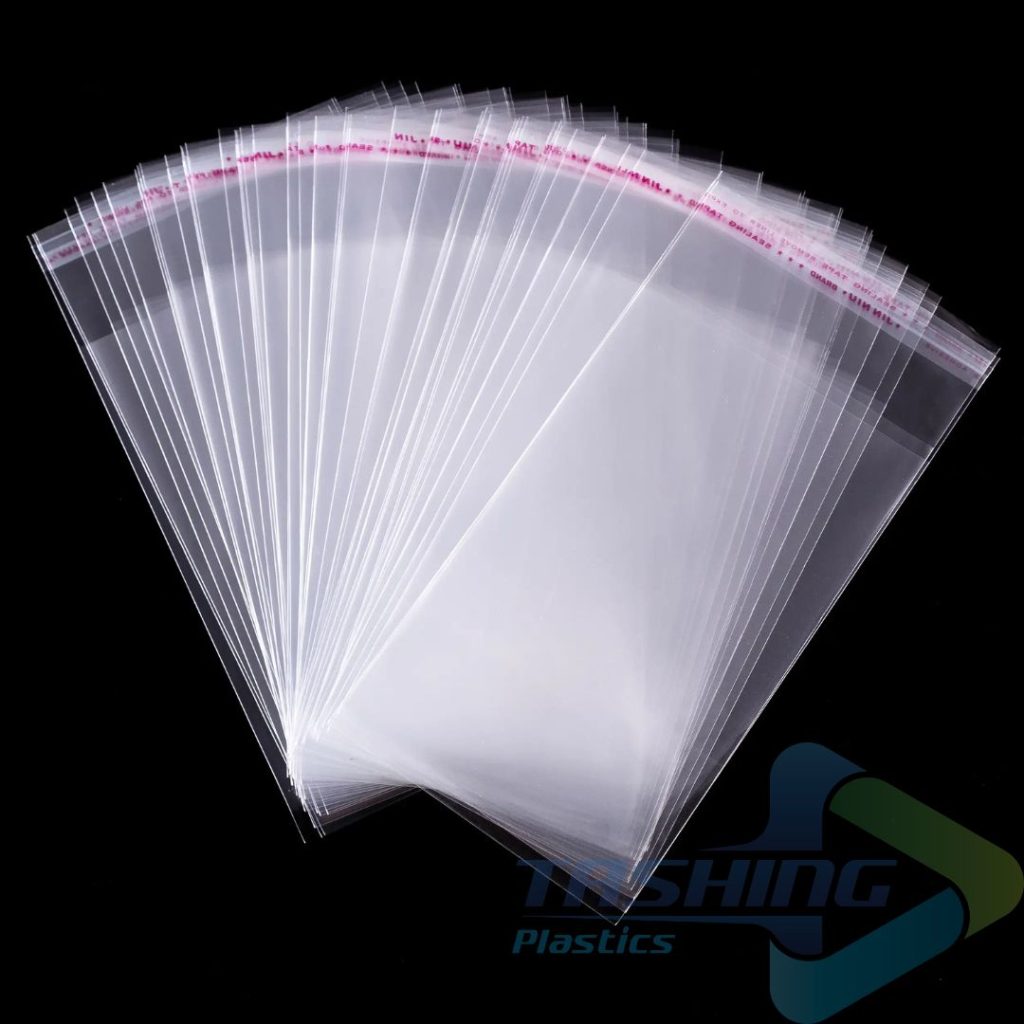

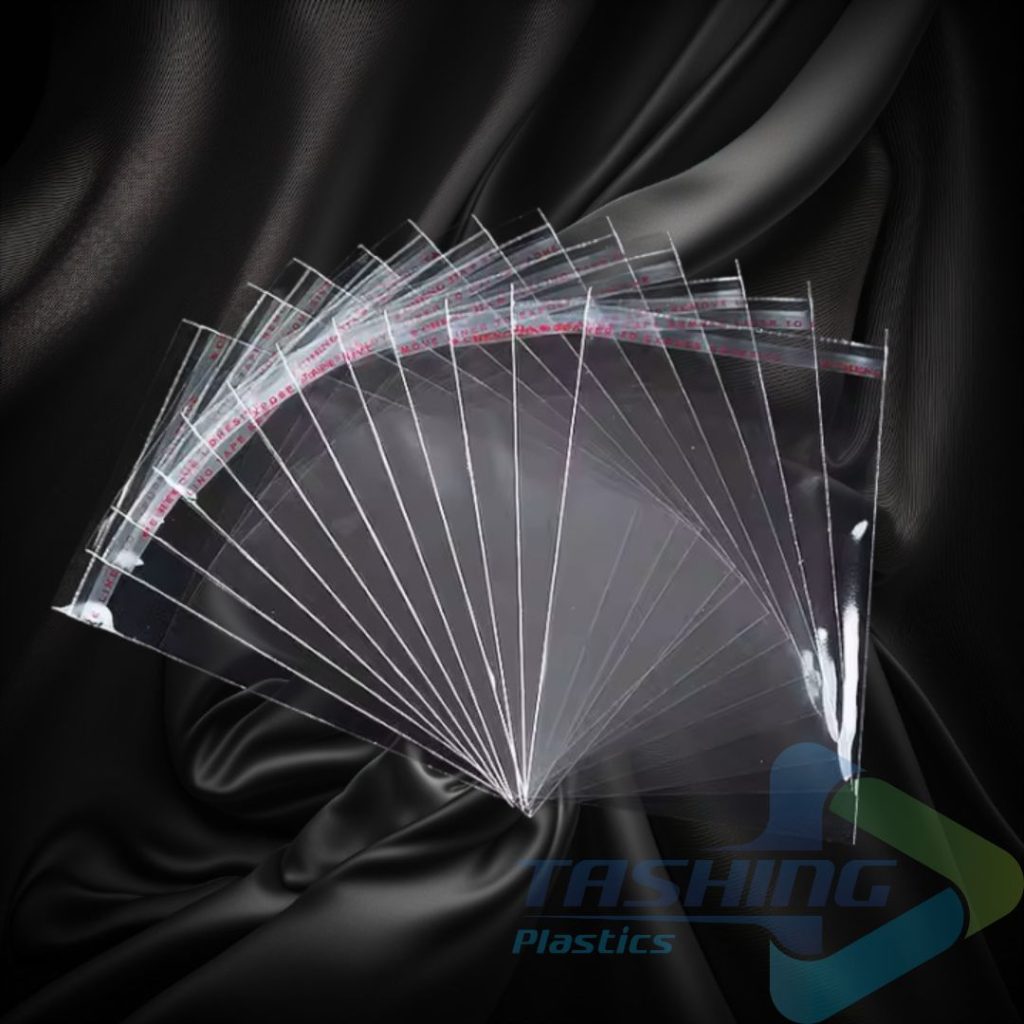

Self-Adhesive OPP Bags

Self-adhesive OPP bags are designed with an adhesive strip on the flap, making it easy to seal without the need for additional tools. These bags are typically made from clear OPP film with a high gloss finish, allowing the contents to be clearly displayed and visually appealing. Due to their convenience and secure sealing capabilities, these bags are ideal for packaging items such as greeting cards, photos, jewelry, and small products.

|

|

-

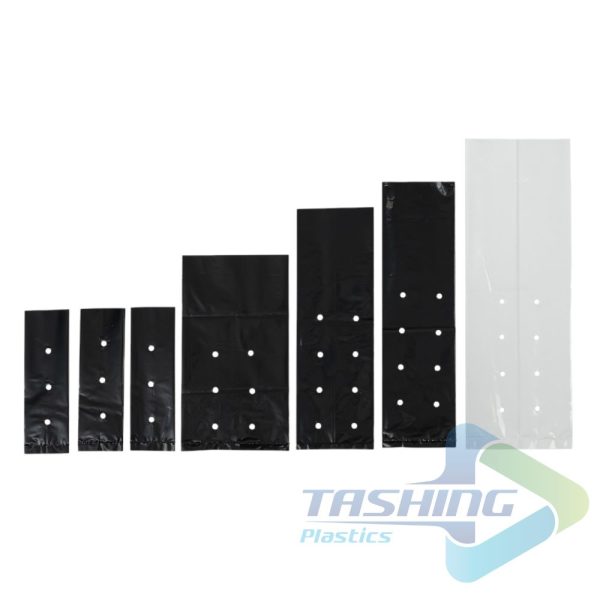

Perforated OPP Bags

Perforated OPP bags have small holes on the surface that allow air circulation, preventing moisture buildup and helping preserve products that are prone to absorbing moisture. This design keeps food items like vegetables and bread dry, fresh, and free from softness or mold. Due to their breathability, these bags are an ideal choice for the food industry and products that require ventilation.

|

|

-

Header OPP Bags

Header OPP bags are equipped with a reinforced plastic strip and a hanging hole, making them easy to display on store shelves. The header section is an ideal place to print product information, logos, or pricing, enhancing brand visibility. These bags are commonly used for packaging small items such as candies, toys, or accessories.

|

|

-

Printed or Custom OPP Bags

Printed or custom OPP bags are designed with a variety of print patterns, such as logos, images, or unique designs, using high-quality printing technology. These bags can combine glossy or matte finishes to create a distinctive style, making products stand out on store shelves. Printed OPP bags are popular for packaging retail products, gifts, and food items that need to display clear information.

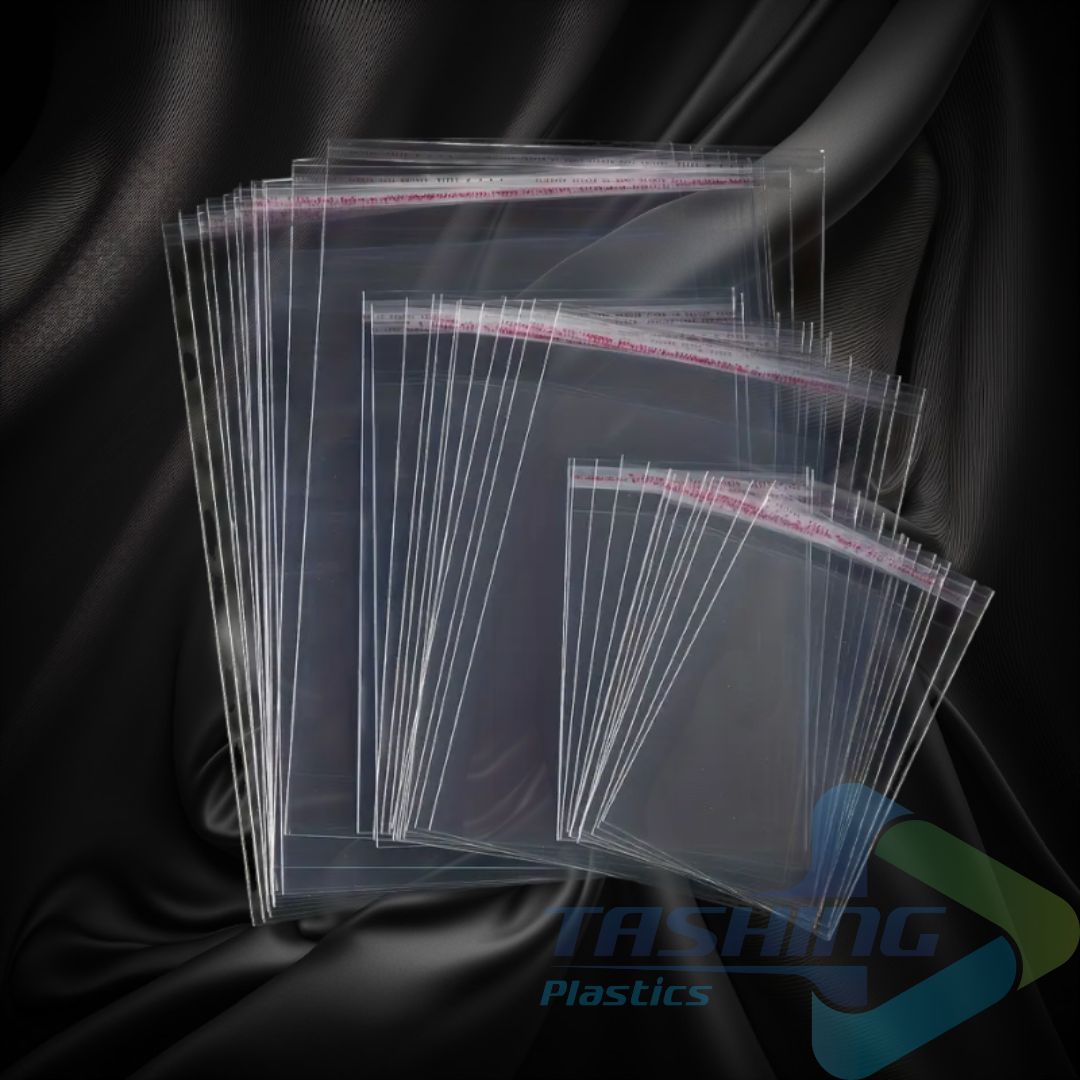

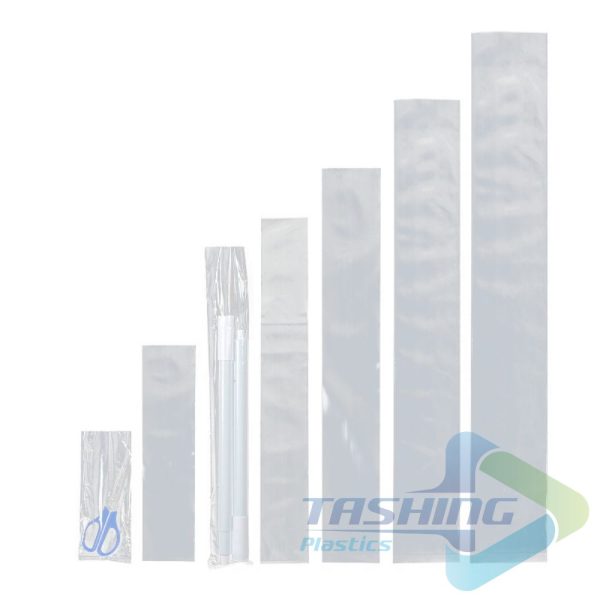

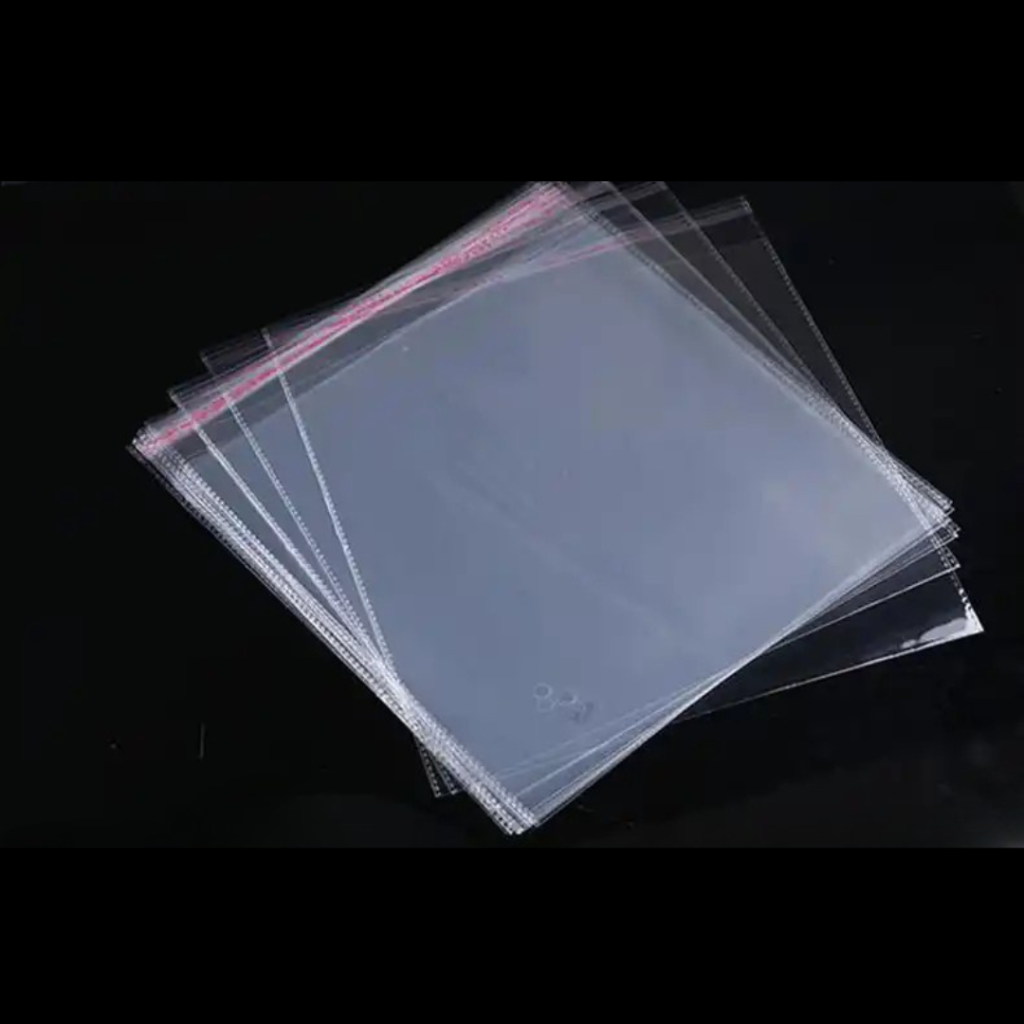

Common Sizes of OPP Bags

| No. | Size (cm) | Common Applications |

|---|---|---|

| 1 | 12 x 22 | Small accessories, souvenirs |

| 2 | 13 x 16 | CD discs, compact products |

| 3 | 15 x 24 | Cosmetics, candies, gifts |

| 4 | 18 x 26 | Thin clothing, personal items |

| 5 | 20 x 30 | Fashion products, small documents |

| 6 | 24 x 35 | A4 documents, household items |

| 7 | 25 x 35 | Common clothing, medium-sized items |

| 8 | 28 x 42 | Thick clothing, medium-sized products |

| 9 | 32 x 45 | Large product sets, household items |

| 10 | 38 x 52 | Large products |

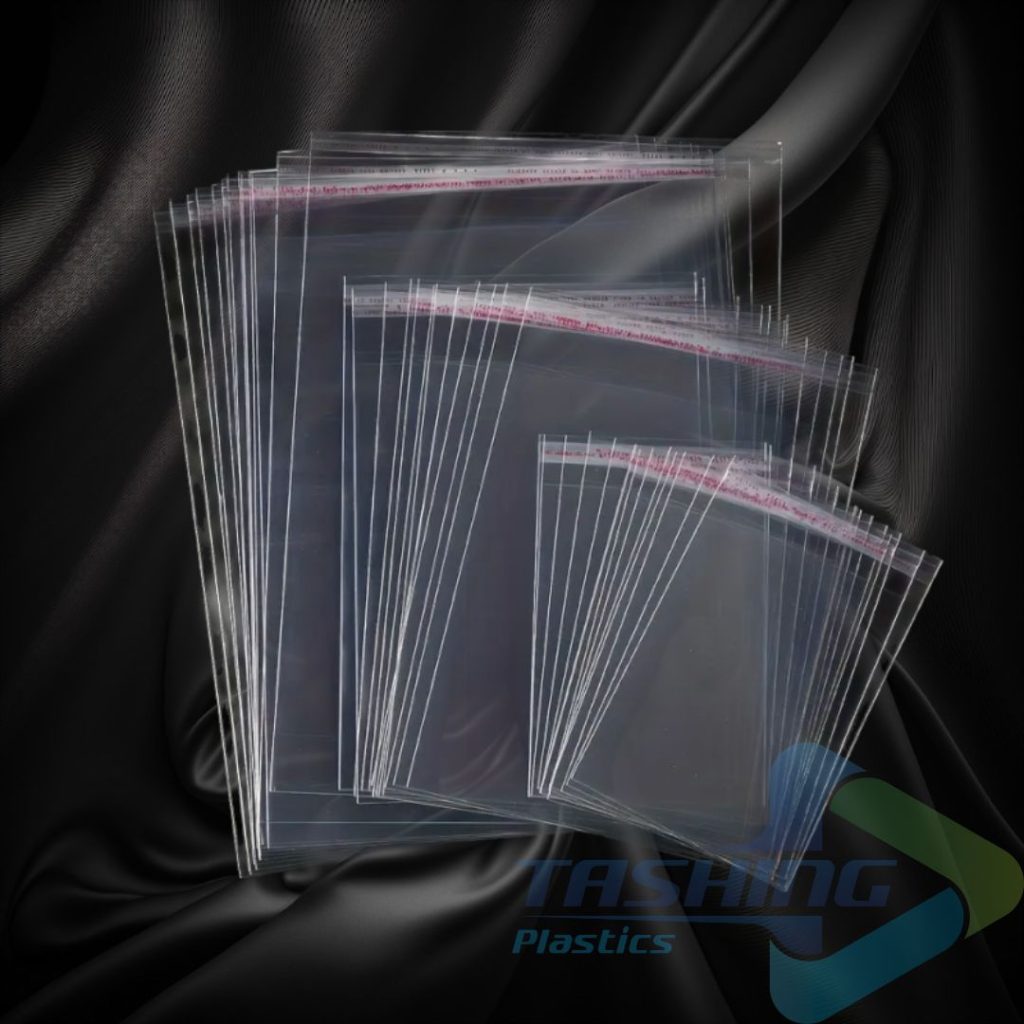

Affordable Self-Adhesive OPP Bag Manufacturer in Ho Chi Minh City

If you’re looking for a reliable supplier of high-quality, affordable OPP bags with a wide range of designs and sizes, Di Đại Hưng Co., Ltd. is a trusted manufacturer and printer of self-adhesive OPP bags in Ho Chi Minh City.

|

|

|

|

|

|

We have a production facility in Ho Chi Minh City, ensuring:

- High-quality, durable self-adhesive OPP bags.

- A wide variety of designs and sizes, with custom production available.

- Competitive pricing due to direct manufacturing, without intermediaries.

- Quick fulfillment of both large and small orders.

- Attractive discounts for bulk orders.

- Fast delivery within Ho Chi Minh City and nationwide shipping support.

Contact Information:

📞 Hotline: 028 3960 5688

📧 Email: info@tashing.com.vn

📘Facebook: Công ty TNHH Di Đại Hưng

For orders or further inquiries, please feel free to contact Di Đại Hưng Co., Ltd. for prompt and dedicated support.