PE or HDPE Roll Laminated with Leather/Fabric

Contact

| Function | Flooring underlayment, waterproofing, wrapping goods, soil covering, pond lining, furniture material production |

|---|---|

| Material | PE or HDPE laminated with synthetic leather, woven fabric, or non-woven fabric |

| Size | Various sizes, customizable upon customer request |

| Thickness | Customizable upon request |

| Color | White, black, gray, or customized colors |

| Features | Durable, waterproof, chemical-resistant, anti-slip, easy to install and customize |

| Packaging | Large rolls, packaging according to customer requirements |

- Description

Description

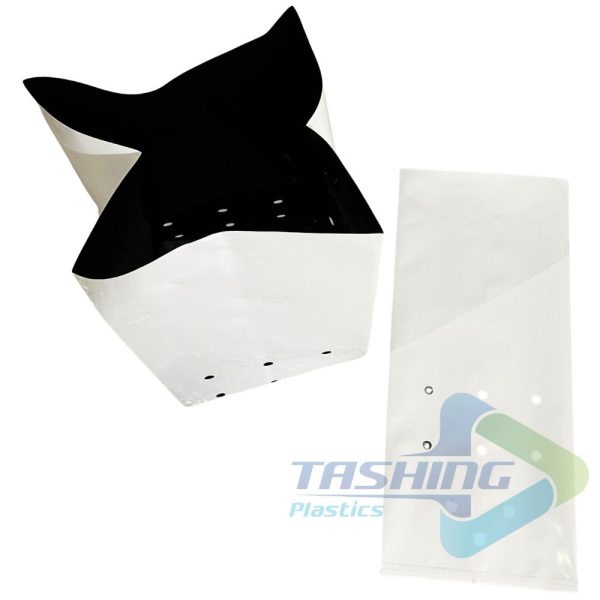

PE or HDPE Roll Laminated with Leather/Fabric is one of the standout products of Di Dai Hung Co., Ltd., offering an optimal solution for various industries thanks to its superior properties and wide range of applications. This product is designed to meet diverse needs in packaging, construction, agriculture, and industrial sectors, combining PE/HDPE plastic with a layer of leather or fabric to create a strong, flexible, and efficient material.

Key Features

The PE/HDPE laminated roll is made from Polyethylene (PE) or High-Density Polyethylene (HDPE), combined with high-quality leather or fabric, delivering excellent performance. One of its most notable advantages is high mechanical strength. Thanks to the HDPE’s low degree of molecular branching, the product offers outstanding impact resistance, tear resistance, and shape retention even under harsh conditions. The added leather or fabric layer not only enhances durability but also improves anti-slip performance, making it ideal for applications requiring high surface friction.

Another critical feature is its absolute water resistance. PE/HDPE plastic is well-known for being waterproof, and when combined with specially treated leather or fabric, this product becomes an ideal choice for moisture-protection applications, such as flooring underlayment in construction or protective wrapping during transportation. Furthermore, it is resistant to chemicals, including acids, alkalis, and common solvents, ensuring stable performance in industrial environments.

Its flexibility is also a major advantage. The product can be easily cut, bent, or processed to meet specific requirements. The leather/fabric layer adds aesthetic value and allows for easy customization for various purposes, from industrial packaging to decorative interior materials.

Modern Manufacturing Process

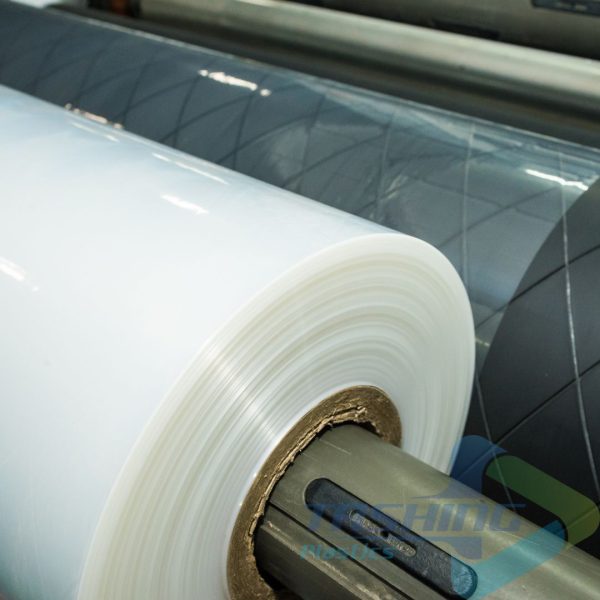

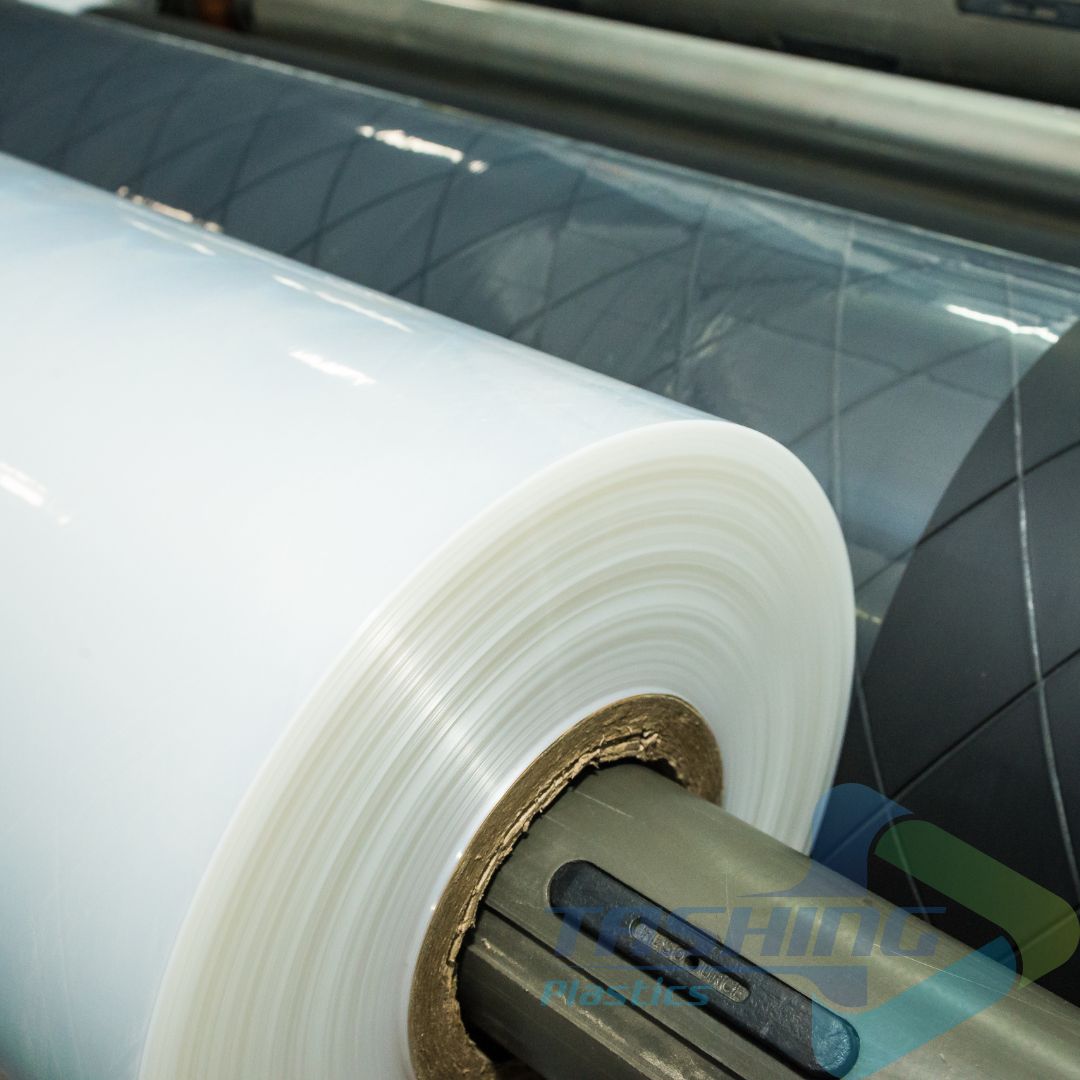

Di Dai Hung Co., Ltd. utilizes advanced technology to produce consistent and reliable PE/HDPE laminated rolls. The process begins with selecting high-quality virgin PE/HDPE resin, which is carefully processed to ensure purity and stability. The resin is then extruded or blown into uniform plastic films of consistent thickness.

The lamination process, either via thermal bonding or specialized adhesives, firmly attaches the leather/fabric to the plastic film without peeling during use. Depending on the application, different materials can be selected for the leather/fabric layer, such as non-woven fabric, synthetic leather, or high-strength woven fabric. After lamination, the product is cooled, strictly quality-checked, and rolled into large rolls, ready for practical use.

Wide Range of Applications

PE/HDPE laminated rolls from Di Dai Hung are widely used across multiple sectors. In construction, the product is used as a waterproof underlayment for foundations, concrete floors, or hydraulic structures. The leather/fabric layer enhances surface adhesion and reduces the risk of slipping during installation, while also protecting the plastic film from damage caused by contact with rough materials.

In packaging and logistics, the roll is an ideal solution for pallet wrapping, protecting goods from impact, scratches, and environmental exposure. The leather/fabric layer offers added strength and aesthetics, making it suitable for high-end products that require careful handling. In agriculture, it is used as mulch film to retain soil moisture, protect crops, or line aquaculture ponds due to its waterproof and durable properties.

Additionally, in the interior industry, this product is used for manufacturing chair covers, mattresses, or decorative surfaces, leveraging the flexibility and visual appeal of the laminated fabric. It also finds applications in innovative uses such as temporary partitions or insulation materials in special constructions.

Benefits of Using the Product

Using PE/HDPE laminated rolls from Di Dai Hung Co., Ltd. offers many practical benefits. The product improves work efficiency thanks to its easy installation and adaptability to various environments. Its high durability and resistance properties help extend the lifespan of structures or goods being protected. Moreover, the combination of PE/HDPE and leather/fabric provides a multifunctional solution that meets the needs of many industries while maintaining aesthetics and performance.

Conclusion

PE or HDPE Roll Laminated with Leather/Fabric from Di Dai Hung Co., Ltd. is an advanced product that perfectly combines the strength of PE/HDPE plastic with the flexibility of leather or fabric. With waterproofing, chemical resistance, durability, and broad applicability, it is increasingly favored in construction, packaging, agriculture, and interior industries. Di Dai Hung is committed to delivering high-quality solutions that meet all customer needs with durable and efficient products.