Exploring PE Film Properties and Where to Purchase

29/06/2024Polyethylene film, also known as PE film, is a versatile and widely-used plastic film material. It’s a thin, flexible sheet made from polyethylene (PE), a type of thermoplastic polymer. PE film is a product of the polymerization process involving ethylene monomers. These monomers, under the influence of heat and pressure, bind together to form long chains of polyethylene molecules, giving rise to the PE film. This film exhibits remarkable PE Film Properties like strength, flexibility, and resistance to moisture and chemicals, making it suitable for a variety of applications. PE film is an essential component of our modern world, making its way into everyday products and various industrial processes.

Types of PE Film: LDPE, LLDPE, HDPE

PE film is classified into different categories based on its density and properties, known as PE Film Properties. These categories play a role in determining the film’s applications; each type excels in specific areas based on its unique characteristics. The most common types of PE films are:

1. Low-Density Polyethylene (LDPE) Film

LDPE film is characterized by its low density and high flexibility. It is one of the most common types of PE film used for various purposes. LDPE’s structure features a branched polymer chain, which accounts for its flexibility and tensile strength. The branching of the polyethylene molecules hinders their ability to pack tightly, resulting in a lower density.

Properties:

- Low Density: Typically ranging from 0.910 to 0.940 g/cm3. This low density gives LDPE excellent flexibility and tear resistance.

- High Flexibility: Easily bends and conforms to different shapes, making it a good choice for packaging and wrapping applications.

- Good Tear Resistance: LDPE’s branched chains provide a strong molecular structure, resulting in good resistance to tearing.

- Good Chemical Resistance: Generally resistant to acids, bases, and alcohols, making it suitable for packaging various chemicals and products.

- Low Cost: Among the different types of PE films, LDPE is usually the most cost-effective option.

Applications:

- Packaging: Commonly used for food packaging, including bags, wraps, and pouches, due to its flexibility and resistance to moisture.

- Trash Bags: LDPE’s strength and moisture resistance make it ideal for trash liners.

- Film Wrap: Used in various industries for wrapping items like furniture, appliances, and construction materials.

- Protective Covers: LDPE can be used to create coverings for protection during construction, painting, or other activities.

2. Linear Low-Density Polyethylene (LLDPE) Film

LLDPE film is a more recent development and is known for its improved strength and puncture resistance. It achieves this strength by incorporating short branches into the polyethylene molecule, creating a more compact and less flexible structure compared to LDPE.

Properties:

- Lower Density: Generally has a lower density than LDPE, ranging from 0.915 to 0.940 g/cm3, while still maintaining good flexibility.

- Increased Strength: LLDPE film has greater puncture resistance and tensile strength than LDPE, making it suitable for demanding applications.

- Improved Sealability: LLDPE forms stronger seals compared to LDPE, making it suitable for packaging applications requiring a tighter seal.

- Good Clarity: LLDPE films can be transparent or semi-transparent, allowing for product visibility.

Applications:

- Heavy-Duty Packaging: Used for packaging heavy or sharp objects, such as construction materials, building supplies, and agricultural products.

- Shrink Wrap: Commonly used for shrink-wrapping products for packaging and transportation.

- Grocery Bags: LLDPE’s strength and sealability make it ideal for grocery bag applications.

- Film Wrap: Used for wrapping various products, including furniture, appliances, and construction materials.

3. High-Density Polyethylene (HDPE) Film

HDPE film stands out for its high density, stiffness, and strength. Its tightly packed linear structure contributes to its rigidity and resistance to puncture and tearing. HDPE is commonly used for products requiring durability and strength. This film has a more rigid nature compared to LDPE and LLDPE, contributing to its versatility in various applications.

Properties:

- High Density: Typically ranges from 0.941 to 0.965 g/cm3. This high density gives HDPE its stiffness and strength.

- High Tensile Strength: HDPE exhibits excellent tensile strength, making it resistant to tearing and punctures.

- Good Chemical Resistance: Resistant to various chemicals, including acids, bases, and solvents, making it suitable for packaging products exposed to these elements.

- Good Barrier Properties: HDPE film has good barrier properties against moisture, oxygen, and grease, making it suitable for protecting sensitive products.

- High Stiffness: It is tougher than LDPE and LLDPE, resulting in its use for packaging applications requiring rigidity.

Applications:

- Bags: Commonly used for shopping bags, garbage bags, and industrial bags due to their strength and durability.

- Bottles: HDPE’s strength and chemical resistance make it ideal for producing bottles for various liquids, including milk, juice, and detergent.

- Containers: Used for creating containers for food, chemicals, and industrial products.

- Film Wrap: HDPE film can be used for wrapping and protecting various products, including furniture, appliances, and construction materials.

Characteristics and Properties PE Film

PE film offers a diverse range of qualities that underpin its wide use in different industries. Key properties that make PE film advantageous include its excellent PE film properties:

1. Strength and Durability

The strong molecular bonds in PE film contribute to its exceptional tensile strength and tear resistance. The film’s ability to withstand high stress and pressure makes it a reliable material for packaging heavy or sharp objects, protecting various products in demanding conditions.

2. Flexibility and Conformability

PE film’s flexibility enables it to bend and conform to various shapes, making it suitable for packaging items of diverse shapes and sizes. This flexibility allows for easy wrapping and sealing, enhancing product protection and presentation.

3. Moisture and Chemical Resistance

PE films are inherently resistant to water, moisture, and many common chemicals. This resistance makes it a suitable material for packaging foods, chemicals, and other products that might be affected by moisture or chemical reactions.

4. Heat Sealability

PE film’s heat sealability allows it to be easily sealed using heat, forming strong bonds that prevent leakage or contamination. This property is vital for constructing various packaging formats, such as bags, pouches, and wraps.

5. Transparency and Printability

PE film can be transparent or opaque, allowing for product visibility or creating an aesthetically pleasing package. Its surface can be printed with various inks and designs, providing branding opportunities and enhancing product presentation.

6. Cost-Effectiveness

PE film is generally a cost-effective material compared to other types of packaging films. Its production process is efficient, and the material is readily available in various thicknesses and sizes, contributing to its affordability.

Applications of PE Film in Everyday Life

PE film permeates daily life, playing a vital role in packaging, protection, and various other applications. Here are some common uses of PE film in everyday life:

1. Food Packaging

PE film is a staple in food packaging, particularly for items like fruits, vegetables, meats, and snacks. Its moisture resistance and flexibility make it suitable for preserving food freshness and extending shelf life.

2. Grocery Bags

PE film is used extensively for grocery bags and shopping bags. Its strength and durability make it ideal for carrying grocery items, with higher density versions providing added strength for heavier loads.

3. Trash Bags

PE films, particularly those made from LDPE, are used for lining trash cans and keeping waste contained. Their moisture resistance and strength are important qualities in this application.

4. Protective Covers

PE film can serve as protective covers for furniture, appliances, or construction materials. It provides a barrier against dust, scratches, and moisture while products are in storage or during transport.

5. Industrial Applications

PE film finds numerous applications in various industries, including:

-

Agriculture: PE film is used in agriculture in various forms, including:

- Mulch film: Laid on the soil’s surface to suppress weeds, retain moisture, and regulate soil temperature.

- Greenhouse covers: PE film creates a controlled environment for plants, protecting them from harsh weather conditions and extending the growing season.

- Silage wrap: Used to store and preserve forage crops like hay and corn by creating an airtight seal that prevents spoilage.

-

Construction:

- Building wraps: PE film acts as a vapor barrier behind claddings to prevent water infiltration and improve energy efficiency.

- Drop cloths and dust sheets: Protect surfaces from dust, debris, and paint spills during construction or renovation projects.

- Healthcare: PE film is used in the healthcare sector for medical packaging and disposable medical equipment. It helps to sterile and protect medical supplies

Manufacturing Process of PE Film

The production of PE film involves a series of steps, starting with the raw materials and ending with the finished film. Here is a breakdown of the typical manufacturing process:

1. Raw Material Preparation

The process begins with polyethylene pellets, which are the basic building blocks of PE film. Polyethylene pellets are typically produced by polymerization and are in the form of small, granular particles.

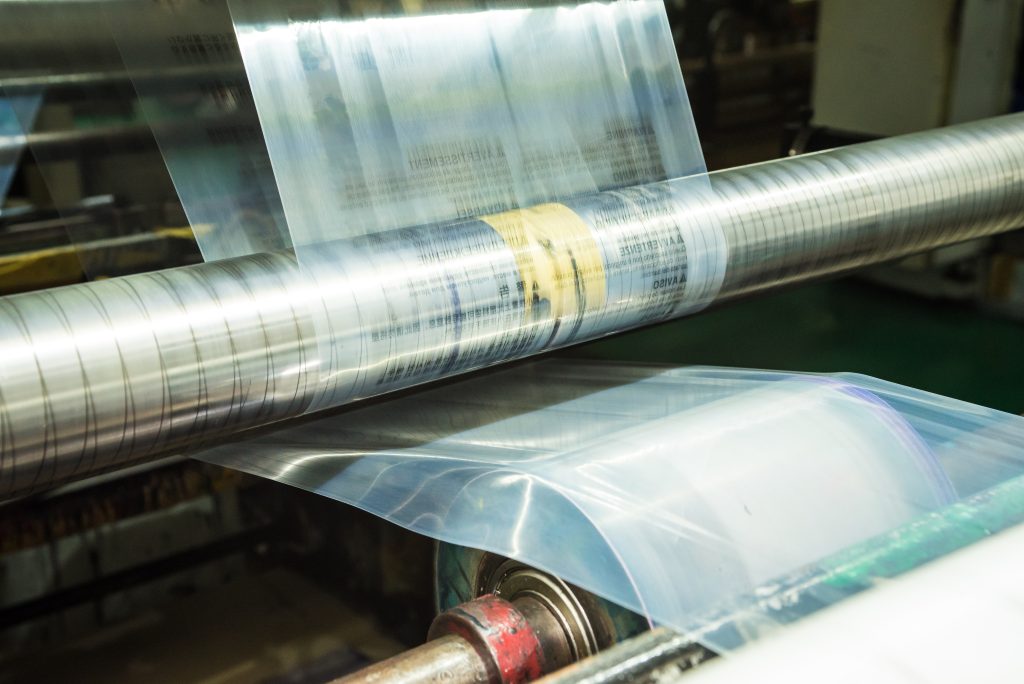

2. Extrusion

The polyethylene pellets are fed into an extruder, a machine that melts the pellets and forces the molten plastic through a die. The die shapes the molten plastic into a continuous film. This extrusion process is the core of PE film production, determining the film’s thickness and other characteristics.

3. Cooling and Winding

The extruded film is then cooled and wound into a roll. This cooling step solidifies the molten plastic, preserving the shape and properties of the film.

4. Inspection and Quality Control

The film is carefully inspected to ensure it meets specific quality standards. This process includes checking for defects, thickness consistency, and adherence to required properties.

5. Conversion and Packaging

After inspection and quality control, the film is converted to its final form. This conversion process may involve cutting, perforating, or printing the film according to specific needs. Finally, the film is packaged and prepared for distribution.

Advantages and Disadvantages of PE Film

PE film offers numerous advantages, contributing to its widespread use in various applications. However, like any material, PE film also has some limitations:

1. Advantages of PE Film

- Versatility: PE film can be tailored to various thicknesses and with different additives, making it suitable for a wide range of applications.

- Low Cost: As mentioned earlier, PE film is generally a cost-effective option compared to other packaging materials.

- Durability: Its strength and tear resistance make it suitable for packaging heavy or sharp objects.

- Moisture Resistance: Its inherent barrier properties help protect products from moisture and humidity.

- Ease of Use: PE film is easily handled and processed, making it convenient for packaging and other applications.

2. Disadvantages of PE Film

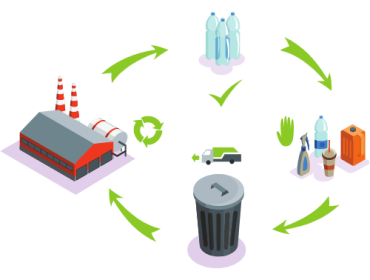

- Environmental Concerns: PE film is a plastic material, and concerns about its environmental impact are growing. Disposing of it improperly can contribute to plastic pollution.

- Durability Issues: While PE film’s durability is generally an advantage, it can also pose a problem for disposal and recycling. It can take a long time for it to decompose in landfills, and it often ends up in the environment, harming wildlife and ecosystems.

- Chemical Leaching: PE film can sometimes leach chemicals into packaged products, especially under specific conditions. This can be a concern for food packaging or products that are sensitive to chemical contamination.

Di Dai Hung Co., Ltd. Producing PE film for export at a factory in Vietnam

Di Dai Hung Co., Ltd. is a reputable company located in Vietnam specializing in the production and export of PE film. Its commitment to producing high-quality PE film tailored to specific customer needs has established it as a leading manufacturer in the region.

The company operates a state-of-the-art factory equipped with advanced machinery and experienced personnel. It adheres to stringent quality control measures to ensure consistent production of high-performance PE film.

Di Dai Hung Co., Ltd. offers a wide range of PE film products, including:

- LDPE film: Widely used for packaging food, general merchandise, bags, and wraps.

- LLDPE film: Suited for heavy-duty packaging, shrink wrap applications, and grocery bags.

- HDPE film: Ideal for bags, bottles, and containers, including industrial and agricultural applications.

The company has established itself as a reliable supplier of PE film to clients across various industries. Its commitment to quality, customer service, and competitive pricing has earned it a strong reputation in the international market.

1. Manufacturing Capabilities

Di Dai Hung Co., Ltd. is equipped with modern manufacturing capabilities that enable it to produce a wide range of PE film products. Its facilities include:

- Extrusion lines: The core of PE film production, its state-of-the-art extrusion lines allow for precise control over film thickness, properties, and characteristics.

- Coating lines: For enhanced product performance, the company offers coating lines that allow for surface treatment and additional layers to customize the film for specific applications.

- Printing facilities: To meet branding and marketing needs, the company provides printing facilities for customizing film designs and incorporating logos and information.

2. Customization Options

The company understands that each customer has unique requirements, and therefore offers a range of customization options to tailor PE film for specific needs. These options include:

- Thickness: Di Dai Hung Co., Ltd. can customize the thickness of PE film, ranging from 8 to 200 micrometers, covering a wide spectrum from thin, lightweight films to thick, robust options.

- Width: The company can produce PE film rolls in various widths, from 2.5 cm to 450 cm, catering to specific packaging and application sizes.

- Colors: PE film can be produced in different colors, which can be useful for branding, product identification, and creating aesthetically pleasing packaging.

- Additives: Various additives can be incorporated into the PE film during the manufacturing process to enhance its properties. For example, additives can be added to improve tear resistance, heat resistance, or UV protection.

3. Quality Control and Certifications

Di Dai Hung Co., Ltd. adheres to strict quality control measures throughout the manufacturing process to ensure the consistency and quality of its PE film products. The company follows internationally recognized standards and has obtained relevant certifications, including:

- ISO 9001: Certification demonstrating the company’s commitment to quality management systems and customer satisfaction.

- Other relevant certifications: The company strives to obtain and maintain certifications relevant to specific industries and applications.

4. Customer Service and Support

Di Dai Hung Co., Ltd. provides responsive and dedicated customer service, supporting clients throughout the entire process, from initial consultation to after-sales support. The company’s sales team is knowledgeable about its products and can assist in selecting the most appropriate PE film for specific applications.

Calculating the Weight of PE Film

Calculating the weight of PE film is super important for both making it and using it. Here are two cool ways to figure out how heavy PE film is:

Using a Formula

When you want to know how much a bunch of PE film bags weigh, using a formula is a smart move. Check out this formula to get the weight: Weight of 1 PE film bag = Length × Width × Thickness × Density of PE

For instance, if you need to find out the weight of a PE film bag that’s 1m x 0.5m with a thickness of 100 micrometers, and made of HDPE (density around 0.94 – 0.96 kg/m³), you can use this formula:

Weight of PE film bag = 1m × 0.5m × 0.0001m × 940 kg/m³ ≈ 0.047 kg

So, the Number of PE films per kg would be: 1 / 0.047 = 21 films/kg

Here’s a neat table showing five different types of Polyethylene (PE) and their densities:

| Type of PE | Density (g/cm³) | Density (kg/m³) |

| Homopolymer | 0.90 – 0.92 | 900 – 920 |

| Copolymer | 0.91 – 0.94 | 910 – 940 |

| HDPE | 0.94 – 0.96 | 940 – 960 |

| LDPE | 0.91 – 0.93 | 910 – 930 |

| LLDPE | 0.92 – 0.94 | 920 – 940 |

This provides a comprehensive overview of how to calculate the weight of PE film and the densities of various types of Polyethylene.

Conclusion

PE film is a versatile and essential material in our modern world, finding its way into numerous applications ranging from everyday packaging to industrial processes. Its strength, flexibility, and resistance to moisture and chemicals make it a valuable material for a multitude of uses, including PE film properties. While its environmental impact needs to be carefully considered, ongoing efforts in recycling and biodegradability are striving to minimize its negative effects.

Di Dai Hung Co., Ltd., a Vietnamese company specializing in PE film production, exemplifies the dedication and innovation within the industry. Its commitment to quality, customer service, and tailoring PE film products to specific needs contributes to its significant role in supplying this essential material to various sectors. The evolution of PE film technology and manufacturing practices continues to shape its role as a key material in various industries, driving advancements in packaging, protection, and other crucial applications