PE bags for carton boxes

Contact

| Functionality: | Protects goods from mold, impact, and dust during transportation and storage. |

| Material: | Virgin Polyethylene (PE) plastic. |

| Size: | Customized according to the size of the carton box and the product, e.g., 65 x 45 x 50 cm. |

| Thickness: | 30 – 100 microns. |

| Color: | Transparent or various colors available. |

| Features: | Waterproof, moisture-resistant, durable, flexible, and able to withstand external impact. |

| Packaging: | Packaged by shipment, depending on customer requirements (can be 10 kg, 25 kg, or as requested) |

- Description

Description

In the context of strong commercial activity and the increasing demand for goods transportation, ensuring the safe preservation and transport of products has become a top priority. PE bags for carton boxes are an important solution in the packaging industry, contributing to the optimization of protecting goods from environmental impacts, ensuring that products remain intact until they reach consumers. From enhancing product quality to increasing brand value, to minimizing costs and optimizing operational efficiency, PE bags for carton boxes have become an indispensable solution in modern supply chains.

What Are PE Bags for Carton Boxes?

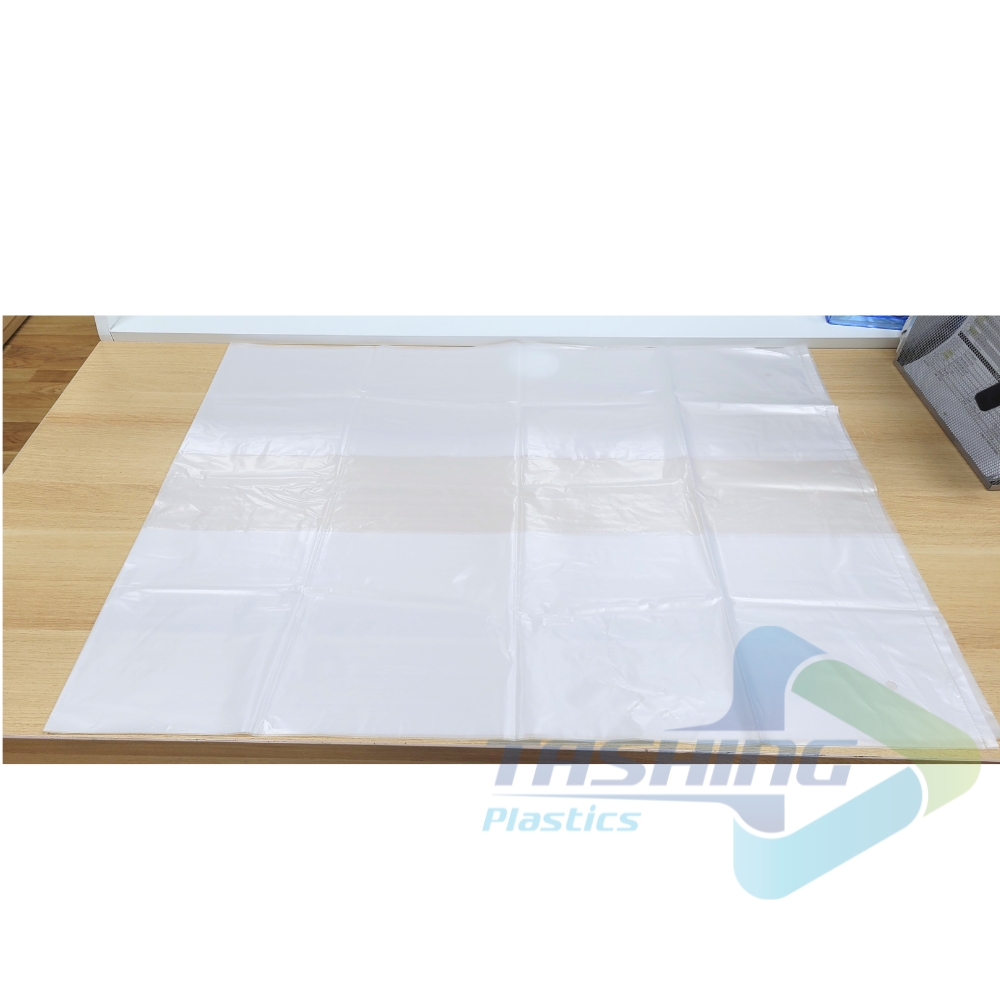

PE bags for carton boxes are a type of packaging made from PE plastic, shaped as square or rectangular bags, used to line the inside of carton boxes. These PE bags act as a protective layer, separating the products from the inner surface of the carton box, thereby helping to preserve goods better during transportation and storage.

|  |  |

Exploring the Superior Features of PE Bags for Carton Boxes

PE (Polyethylene) bags made from virgin plastic offer exceptional characteristics that make them the top choice for lining carton boxes. The combination of waterproofing, high durability, and flexibility of PE bags creates a comprehensive solution for protecting goods, meeting the ever-increasing market demands.

Waterproof Ability & Protecting Goods from Moisture

The waterproof feature is one of the standout advantages of PE bags for carton boxes. With a special molecular structure, PE bags form a barrier that completely prevents the infiltration of water, moisture, and other liquids. This is extremely important for preserving products that are easily affected by humidity, such as food, pharmaceuticals, and electronic devices.

Imagine an electronic shipment carefully packed in a carton box, lined with a PE bag. As the package moves through various weather conditions, from light drizzle to heavy rain, the PE lining will completely block water from entering. This not only protects sensitive components from damage but also helps maintain the quality and operational efficiency of the product.

In the food sector, the waterproof characteristic of PE bags plays a crucial role in preserving fresh and frozen products. Fresh vegetables, seafood, meat, and dairy products are often very susceptible to spoilage due to mold and bacterial attacks. Using PE bags to line cartons will prevent these issues, extending storage time and helping to keep food fresh and safe.

High Durability, Resistant to External Impacts

PE plastic possesses the ability to withstand pressure and high durability, enabling PE bags for carton boxes to withstand strong impacts from the surrounding environment. From impacts and friction during transportation to harsh weather conditions such as heat and low temperatures, PE bags demonstrate superior durability.

When carton boxes containing goods are stacked in warehouses or transported by trucks and containers, the PE lining acts as a protective layer, separating the goods from the external environment. It minimizes impacts such as humidity, scratches, and dents, ensuring the goods remain intact and preserving the aesthetic quality of the products.

In the industrial sector, metal, glass, and ceramic products are often very fragile during transportation. In addition to protection with foam, PE bags for carton boxes also provide a safe cushion, reducing the impact of collisions and minimizing the risk of breakage or cracking of the products. The use of PE bags not only reduces losses of goods but also saves on repair and replacement costs, enhancing the economic efficiency for businesses.

Flexibility & Diversity in Size and Color

One of the notable advantages of PE bags for carton boxes is their variety in size and color. This allows customers to choose the most suitable bag for each type of product and usage requirement.

Current PE bag manufacturers have applied advanced technology to create products in various sizes, from small bags for packaging cosmetics and personal items to large bags for lining containers for household goods and building materials. The ability to customize sizes helps customers optimize storage space, reduce waste, and enhance usability.

Additionally, PE bags are produced in various colors to meet branding and aesthetic needs. For example, companies can choose PE bags printed with their brand logo in colors that match their products, creating a highlight and enhancing brand recognition. The use of colored PE bags makes it easier to categorize goods in storage, saving time and effort for employees.

Cost Savings

PE bags for carton boxes provide economic efficiency, reducing costs for businesses. Compared to other packaging materials, the cost of PE bags is relatively low, allowing businesses to save a significant amount of money.

Furthermore, using PE bags minimizes the risk of goods damage, thereby reducing losses and compensation costs for customers.

Diverse Applications of PE Bags for Carton Boxes in Various Industries

PE bags for carton boxes have become a popular packaging solution across various sectors, from food and consumer goods to electronics and industry. The standout characteristics of PE bags, such as waterproofing, high durability, and flexibility, have contributed to their diverse applications, providing optimal economic and preservation efficiency.

Food & Agricultural Sector

The food and agricultural sector is one of the most significant application areas for PE bags for carton boxes. With waterproof characteristics and limited bacterial infiltration, PE bags help preserve vegetables, fruits, and seafood for longer periods.

Using PE bags helps maintain the freshness and natural colors of food products. Fruits like strawberries, grapes, and oranges are often prone to bruising during transportation. Utilizing PE lining in carton boxes will minimize this occurrence, helping to protect products intact until they reach consumers.

For frozen products like meat, fish, and ice cream, PE bags create an insulation layer, helping to maintain cold temperatures and prevent the growth of bacteria, ensuring food safety.

Electronics & Household Appliance Industry

In the electronics industry, components and electrical devices are often very sensitive to humidity and dust. PE bags for carton boxes create a safe protective layer that prevents the intrusion of these harmful agents.

When packaging electronic products like phones, computers, and TVs, using PE lining in boxes will help protect internal circuit boards and components from moisture, rust, and ensure stable and durable product performance.

Notably, electronic products are often transported through many locations and varying weather conditions. PE bags for carton boxes help minimize the impact from the external environment, contributing to reducing damage from impacts and scratches during transportation.

Industrial & Construction Sector

The industrial and construction sectors also widely use PE bags. Products such as building materials and machinery are often large in size and susceptible to damage during transport.

PE bags play a crucial role in protecting these products from dust, moisture, and impacts during transport and storage.

Additionally, using PE bags helps minimize risks during transport, ensuring the safety of workers and the surrounding environment.

Textile & Fashion Industry

The textile and fashion industry also utilizes PE bags for carton boxes to preserve and transport clothing products. The use of PE bags helps protect clothes and fashion accessories from dust, moisture, and maintain the beauty and quality of the products.

Outstanding Advantages of Using PE Bags for Carton Boxes

The use of PE bags for carton boxes offers many practical benefits for businesses and consumers. From preserving products and protecting brands to minimizing costs and enhancing operational efficiency, PE bags have become a top choice in modern packaging.

Comprehensive Protection of Goods & Enhancing Product Quality

PE bags play an important role in protecting products from environmental impacts such as moisture, dust, and impacts. This helps maintain the quality and aesthetic appeal of products, increasing customer satisfaction.

Fragile products like glassware, porcelain, and ceramics will be optimally protected when using PE bags in carton boxes. The PE lining absorbs impact forces, minimizing the risk of breakage or cracking of the products.

For food products, using PE bags helps prevent bacterial infiltration, keeping food fresh and safe for consumption.

Minimizing Losses & Saving Operational Costs

The use of PE bags for carton boxes helps reduce goods losses during transportation and storage. This allows businesses to save a significant amount of money, enhancing economic efficiency.

Reducing product damage also contributes to minimizing warranty and compensation costs, enhancing the company’s reputation.

Additionally, using PE bags helps reduce packaging and boxing costs, saving time and effort for employees.

Enhancing Brand Reputation & Optimizing Operations

The use of carton box liners demonstrates professionalism and concern for product quality from businesses. This helps enhance brand reputation, attract customers, and build loyalty.

Using PE bags helps optimize transportation and storage processes. Scientifically and safely packing goods saves time and effort for employees, improving the operational efficiency of businesses.

Common Sizes of Carton Box Liners

The sizes of carton box liners do not have a fixed standard but are often customized according to the dimensions of the carton box and the products inside. However, there are some common sizes widely used in manufacturing and packaging.

Factors affecting the size of carton box liners:

- Carton box size: The liner needs to fit snugly or be slightly larger than the internal dimensions of the box to ensure that goods are completely wrapped.

- Product size: The liner must be large enough to contain the product and have enough space to stack products on top of each other.

- Product material: If the product is fragile or has a special shape, the liner must be designed to fit more snugly to ensure safety during transport.

- Usage purpose: Liners used for moisture resistance, dust protection, or impact protection will have different sizes and materials.

Below is a table of PE bag sizes for carton boxes, designed to fit common carton box sizes to protect the goods inside:

| Carton Box Size (LxWxH) | PE Bag Size (LxWxH) | PE Bag Thickness | Application |

|---|---|---|---|

| 60 x 40 x 40 cm | 65 x 45 x 50 cm | 0.05 – 0.1 mm | Lining large boxes, protecting fragile items, electronics |

| 50 x 40 x 40 cm | 55 x 45 x 50 cm | 0.05 – 0.1 mm | Packaging electronic devices, clothing |

| 40 x 30 x 30 cm | 45 x 35 x 40 cm | 0.03 – 0.07 mm | Lining compact goods, food products |

| 30 x 20 x 20 cm | 35 x 25 x 30 cm | 0.03 – 0.07 mm | Protecting small items, fashion accessories |

| 20 x 15 x 15 cm | 25 x 20 x 20 cm | 0.03 – 0.07 mm | Packaging cosmetics, small household items |

Note: The sizes and thicknesses may vary based on manufacturer specifications.

Choosing the Right PE Bags for Carton Boxes

Selecting suitable PE bags for carton boxes is crucial to ensure the protection and preservation of products during transport. Here are some key considerations when choosing PE bags:

- Size: Choose PE bags that fit the internal dimensions of the carton box, ensuring they are snug enough to cover and protect the goods inside.

- Thickness: Depending on the level of protection needed, consider the thickness of the PE bags. Thicker bags will provide better impact resistance and moisture protection.

- Quality: Select high-quality PE bags made from virgin plastic to ensure durability and waterproofing.

- Branding: If desired, choose PE bags that can be printed with your brand logo or designed with colors that match your products for better visibility and marketing.

- Usage Purpose: Depending on the product being packaged (fragile, food, etc.), select the appropriate type of PE bags to meet specific requirements.

Conclusion

PE bags for carton boxes have become an indispensable solution in modern packaging. With their waterproofing, durability, flexibility, and cost-effectiveness, they provide a comprehensive solution for protecting goods across various sectors. From the food industry to electronics and textiles, the outstanding features of PE bags help preserve product quality and enhance brand reputation. Selecting the right PE bags will contribute significantly to operational efficiency and economic savings for businesses