What is flexible packaging and what materials are used?

17/04/2025In the modern context, where goods are produced and exchanged in massive quantities, flexible packaging has become an indispensable element in preserving, transporting, and promoting products. With outstanding features such as flexibility, convenience, and cost-effectiveness, flexible packaging has increasingly affirmed its important position in the market. From preserving fresh food to maintain its freshness, to packaging cosmetics and pharmaceuticals that meet safety standards, and ensuring the safe and efficient transportation of goods worldwide, flexible packaging plays a vital role in the development of the economy and human life. This article will provide a comprehensive overview of common types of flexible packaging, along with their advantages, disadvantages, applications, and sustainable development directions for the future.

What is flexible packaging?

Flexible packaging, also known as soft packaging, is a type of packaging made from non-rigid materials—typically flexible substances that can bend and conform to the shape of the product inside. Unlike rigid packaging such as bottles or cardboard boxes, flexible packaging can be rolled, folded, and is easy to transport and store. This flexibility has significantly contributed to its wide range of applications across various industries.

Key features of flexible packaging include:

Flexibility: Flexible packaging can be easily bent, folded, and shaped as desired, saving storage and transportation space.

Product-conforming ability: It can closely wrap around the product, preventing impact and reducing damage during transportation—especially useful for fragile or easily deformed items.

Lightweight: Compared to rigid packaging, flexible packaging is much lighter, helping to reduce transportation costs and save energy.

Material variety: Flexible packaging is made from a wide range of materials such as plastic (PE, PP, PET), paper, non-woven fabric, aluminum, and more. Each type has specific characteristics suited for different usage needs.

Thanks to these outstanding features, flexible packaging is increasingly used in various fields—from food, cosmetics, and pharmaceuticals to industrial and electronic products.

Common Types of Flexible Packaging

In a world filled with a wide variety of goods, choosing the right type of packaging is essential for protecting products, ensuring consumer safety, and optimizing transportation and storage. Thanks to its versatility in materials and structure, flexible packaging offers a wide range of options to meet the growing demands of the market.

Plastic Packaging: PE, PP, PVC, PET

Plastic is one of the most commonly used materials in flexible packaging due to its flexibility, durability, and relatively low cost.

The most widely used plastics in the production of flexible packaging include:

Polyethylene (PE): This is the most common plastic used for packaging food, beverages, and household products. PE is flexible, transparent, easy to process and seal. It offers good resistance to water, moisture, and grease, making it especially suitable for preserving fresh foods and beverages that require dry storage conditions.

Examples: Packaging for milk, fruit juice, and ready-to-eat food products.

PE comes in several types, each with specific characteristics suited to different applications:

HDPE (High-Density Polyethylene): Known for its rigidity, strength, and impact resistance, HDPE is often used in packaging that requires durability, such as shampoo and body wash bottles.

LDPE (Low-Density Polyethylene): This type is softer and more flexible, commonly used for plastic bags and food packaging.

- Polypropylene (PP): This type of plastic is known for its transparency, high durability, and better heat resistance compared to PE. It also has excellent water and moisture resistance. PP is commonly used for packaging products that need to be preserved in high-temperature environments or protected from moisture, such as dried food, beverages, and household items. Additionally, PP is used for food wrap films, packaging for cosmetic products, or any items that require high transparency.

- Polyvinyl Chloride (PVC): PVC is a type of plastic known for its rigidity and good mechanical strength. One of its main advantages is its resistance to water, moisture, and chemicals. It is commonly used to produce food wrap films and packaging for chemical products and electronic items. However, PVC also has some limitations, such as being prone to degradation by UV rays and the potential release of harmful substances that may negatively impact human health and the environment.

- Polyethylene Terephthalate (PET): PET is a transparent plastic with high strength, good impact resistance, and excellent barrier properties against gases, moisture, and chemicals. It is commonly used to make bottles for soft drinks, cooking oil, sauces, and other products that require high transparency, allowing the contents inside to remain clearly visible.

Paper Packaging: Kraft Paper, Couche Paper, Metallized Paper

Paper packaging is an eco-friendly alternative to plastic flexible packaging. Various types of paper are used in flexible packaging, each with its own unique properties suited to different applications.

- Kraft Paper: Kraft paper is characterized by its natural brown color and is made from unbleached virgin wood pulp. It is known for its high strength, good durability, and acceptable resistance to water and moisture. As a result, it is widely used for packaging products such as dry food and industrial goods. One of the key advantages of Kraft paper is its environmental friendliness—it is biodegradable and helps reduce the negative impact on the environment.

- Couche Paper: Couche paper features a smooth, glossy surface coated with a special material that enhances print quality, making colors appear sharper and more vibrant. It is often used in the packaging of premium products such as cosmetics, dietary supplements, and pharmaceuticals due to its luxurious and eye-catching appearance. However, one drawback of Couche paper is its lower resistance to water and moisture compared to Kraft paper. To improve durability and product protection, it typically requires an additional plastic film lamination.Metallized Paper: Metallized paper is coated with a thin layer of metal, giving it a modern and luxurious appearance. This paper has reflective properties that help protect products from UV rays. It is commonly used for packaging items like coffee, tea, premium food products, cosmetics, and other items that need to be shielded from sunlight.

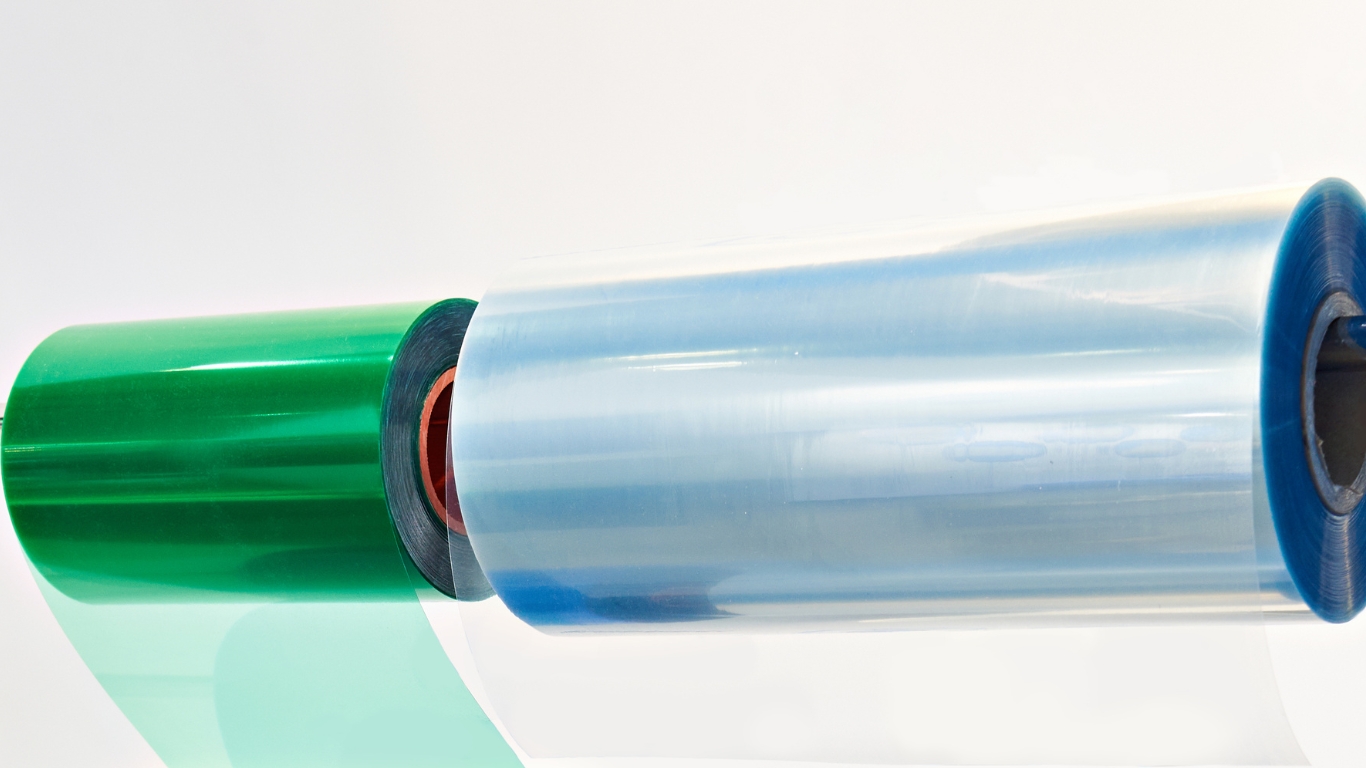

Composite Packaging: Multi-layer Laminated Packaging

Composite packaging is made by laminating multiple layers of different materials, combining the strengths of each layer to create a packaging solution with enhanced functionality.

- Combination of different plastics: For example, an inner PE layer provides water resistance, while an outer PP layer adds rigidity and strength.

- Combination of plastic and paper: Paper offers structural integrity and excellent printability, while plastic enhances moisture resistance and product protection.

- Combination of plastic and metal: This type of packaging protects products from environmental impacts, prevents oxidation, and helps preserve the flavor and quality of the contents.

Composite packaging is increasingly popular in the market as it meets high standards for preservation, transportation, and visual appeal. For instance, yogurt packaging typically consists of an inner PE layer to hold the yogurt, an aluminum layer to block out light, and an outer PP layer to add strength.

Fabric Packaging: Non-woven Fabric, Woven Fabric

Fabric packaging is an eco-friendly solution that helps reduce the use of plastic in product packaging.

- Non-woven Fabric: This type of fabric is made from synthetic or natural fibers that are bonded together through heat or chemical processes. Non-woven fabric packaging offers many advantages such as being environmentally friendly, biodegradable, reusable, and highly absorbent. It is widely used for packaging items like clothing, toys, and fresh food.

- Woven Fabric: Woven fabric is made from natural fibers such as cotton or linen, or synthetic fibers like polyester. It is highly durable, reusable, and aesthetically pleasing, making it a popular choice for packaging premium products such as garments and household goods. However, woven fabric can absorb water easily, is prone to wrinkling, and may take longer to decompose compared to non-woven fabric.

Advantages of Flexible Packaging

Flexible packaging offers many outstanding advantages compared to rigid packaging, contributing to improved efficiency in product preservation, transportation, storage, and display.

Good Product Preservation Capability

- Water and moisture resistance: Flexible packaging made from PE, PP, or composite materials has excellent water and moisture resistance, helping to protect products from mold, damage, and spoilage during transportation and storage. This is particularly important for food, beverages, and electronic products sensitive to moisture.

- Anti-oxidation and UV protection: Some types of flexible packaging are made from materials that can resist oxidation and UV rays, preventing the products inside from deteriorating, and preserving their color, flavor, and original quality. For example, coffee and tea packaging is often made from materials that resist oxidation, helping to maintain the delicious flavor of the product.

- Protection from environmental impact: Flexible packaging can tightly fit around the product, protecting it from external impacts such as bumps, scratches, dust, and other factors. As a result, products are transported and stored more safely, minimizing damage during transportation and storage.

Flexibility and Ease of Use

- Easy to pack and transport: Flexible packaging can be folded compactly, making it easy to pack and saving storage and transportation space. As a result, shipping costs are significantly reduced, making it suitable for various types of transportation, including road, sea, and air.

- Convenience for consumers: Flexible packaging is typically lightweight, easy to handle, and user-friendly. Consumers can easily open the packaging and use the product conveniently. Packaging with handles or carry straps also makes it easier to carry and transport the product.

- Variety in shapes and sizes: Flexible packaging can be designed in various shapes and sizes to suit different products, from small items to larger ones. It can also be printed with a wide range of colors and patterns, enhancing the product’s aesthetic value and attracting consumers’ attention.

Lightweight and Cost-Effective Shipping

- Reduced weight: Flexible packaging is typically very lightweight, helping to reduce the overall weight of the product, which in turn lowers shipping costs and fuel consumption. This is especially important for products being shipped over long distances, reducing transportation expenses and contributing to environmental protection.

- Optimized storage space: Flexible packaging can be easily stacked, helping to maximize storage space in warehouses, factories, and stores. This reduces warehouse rental costs and optimizes available space.

- Energy savings: Using lightweight flexible packaging helps reduce energy consumption during transportation, which protects the environment and minimizes the negative impact on climate change.

Environmentally Friendly (for Some Types)

- Recycled materials: Some flexible packaging is made from recycled materials, helping to reduce the use of natural resources and minimize waste released into the environment.

- Biodegradable: Flexible packaging made from materials like corn starch or bioplastics is biodegradable in nature, causing no environmental pollution.

- Reduced plastic usage: Using flexible packaging made from paper, fabric, or other environmentally friendly materials helps reduce plastic use, contributing to environmental protection and human health.

Disadvantages of Flexible Packaging

While flexible packaging offers numerous advantages, there are also some drawbacks that need to be considered in order to choose and use the most suitable type of packaging.

Prone to Tears and Punctures

- Low resistance to force: Flexible packaging generally has lower strength compared to rigid packaging. If not designed and produced carefully, flexible packaging can easily tear or puncture during transportation, storage, or when consumers use it.

- Affected by mechanical impacts: Flexible packaging is vulnerable to tears and punctures when exposed to sharp objects, strong impacts, or excessive stretching. This can lead to product damage, affecting the quality and value of the product.

- Care needed during use: Consumers need to be cautious when using flexible packaging to avoid tearing or puncturing it, which could compromise the product’s quality during storage and use.

Poor Heat Resistance

- Deformation at high temperatures: Some flexible packaging made from PE or PP plastic can soften and deform when exposed to high temperatures, potentially affecting the product inside.

- Decreased product quality: Storing products in flexible packaging under high-temperature conditions may reduce the product’s quality, causing color, flavor, or structural changes, or even leading to product degradation.

- Limited use in high-temperature environments: It’s important to avoid using flexible packaging in high-temperature environments or to opt for packaging materials with better heat resistance, such as composite packaging.

Applications of Flexible Packaging in Various Industries

Flexible packaging, with its versatility and convenience, is widely used across various industries, from food and apparel to chemicals and pharmaceuticals, playing a crucial role in product preservation and safe, efficient transportation.

Food Industry: Packaging for Fresh and Processed Foods

Flexible packaging plays a key role in the food industry, helping to preserve fresh food, maintain quality, and facilitate the convenient transportation and storage of food products.

- Packaging for fresh food: Flexible packaging made from PE, PP, or composite films, which are water, moisture, and grease resistant, is ideal for packaging fresh food products such as vegetables, fruits, meat, fish, and seafood. It helps maintain freshness and quality while protecting the food from bacteria and spoilage during transportation and storage.

- Packaging for processed food: Flexible packaging such as plastic bags and food wraps are widely used for packaging processed food items like candies, instant noodles, and frozen products. This type of packaging helps preserve food for extended periods, protecting it from environmental factors and preventing contamination from other food products.

Apparel Industry: Packaging for Clothing and Fashion Accessories

- Protecting clothes from environmental factors: Flexible packaging like plastic bags and non-woven fabric bags are commonly used to package apparel and fashion accessories. This packaging helps protect the products from dust, environmental influences, and helps maintain the shape and quality of the items during transportation.

- Enhancing product aesthetics: Flexible packaging can be designed in various colors and patterns, boosting the aesthetic value of the product and attracting consumer attention. Fashion brands often use flexible packaging with printed logos and product information to promote their brand and create a strong impression on customers.

Chemical Industry: Packaging for Chemicals and Solutions

- Protecting users and the environment: Chemicals and solutions are often corrosive and can pose dangers to both users and the environment if not packaged and stored properly. Flexible packaging made from materials such as PVC, PET, or composite films has excellent leak-proof and moisture-resistant properties, helping to protect both users and the environment from the harmful effects of chemicals.

- Safe storage and transportation of chemicals: Flexible packaging can be designed in various sizes and shapes to suit different chemicals and solutions. This type of packaging helps preserve chemicals by preventing evaporation, leaks, and ensuring safe transportation, minimizing risks during transit.

Pharmaceutical Industry: Packaging for Medications and Dietary Supplements

- Ensuring quality and food safety: Pharmaceutical products and dietary supplements need to be stored under strict conditions to maintain their quality and efficacy. Flexible packaging made from specialized materials that offer moisture and oxidation resistance helps protect these products from deterioration, contamination, and ensures quality and safety for users.

- Protecting products from light and air: Some medications and dietary supplements can degrade when exposed to sunlight or air. Flexible packaging can be designed to block light and prevent exposure to air, preserving the product’s quality and minimizing degradation, ensuring maximum effectiveness.

The Role of Flexible Packaging in Product Preservation and Transportation

Flexible packaging plays an important role in protecting products, maintaining quality, and ensuring safety throughout the processes of transportation, storage, and consumption.

Protecting Products from Environmental Factors

- Impact and Scratch Resistance: Flexible packaging has the ability to absorb impact forces, minimizing the external forces acting on the product and protecting it from scratches and dents.

- Dust and Water Resistance: Flexible packaging made from plastic or composite films is highly effective in protecting products from dust and water, keeping products clean and dry.

- Insect and Bacteria Protection: Packaging helps prevent insects and bacteria from entering the product, safeguarding it from contamination and ensuring food safety.

Maintaining Product Quality and Freshness

- Preventing Oxidation and Degradation: Some types of flexible packaging are made from materials with anti-oxidation properties, helping to maintain the freshness of food products and preserving their taste and quality.

- Preserving Freshness of Food: Flexible packaging is designed to retain moisture, helping to maintain the freshness of food products and extend their shelf life.

- Protecting Color and Flavor: Packaging helps protect the product from sunlight and air, preventing changes in color and flavor, thereby preserving its quality.

Reducing Losses and Damage During Transportation

- Minimizing Transportation Risks: Flexible packaging helps reduce the risk of damage during transportation, protecting the product from impact and scratches, thereby minimizing product loss.

- Reducing Costs of Handling Damaged Goods: Using appropriate flexible packaging helps reduce losses from damaged products, saving on costs associated with handling damaged goods and improving business efficiency.

- Ensuring Food Safety: Flexible packaging contributes to food safety by minimizing bacterial growth, protecting consumer health.

The Impact of Flexible Packaging on Health and the Environment

The use of flexible packaging not only brings many benefits to consumers and businesses but also poses some potential negative effects on health and the environment.

The Impact of Chemicals in Packaging on Human Health

- Release of Harmful Chemicals: Some types of flexible packaging, especially those made from PVC plastic, may contain harmful chemicals like BPA, phthalates, etc. These substances can be released into the environment during use and can easily enter the human body through food or direct contact.

- Choosing Safe Packaging: To ensure health safety, consumers should choose flexible packaging made from materials that are free from harmful chemicals, especially when used for packaging food and beverages.

See more: Choose Safe Food Storage Bags: Your Guide to Freshness and Health!

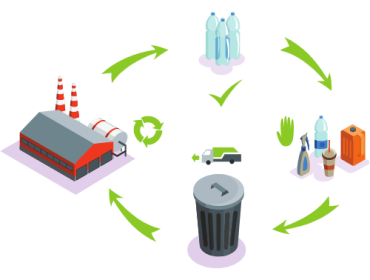

Solutions to Mitigate the Negative Impact of Flexible Packaging

To reduce the negative effects of flexible packaging on human health and the environment, appropriate solutions are necessary.

Recycling and Reusing Packaging

- Building a Packaging Collection and Recycling System: An effective system for collecting and recycling flexible packaging needs to be established, encouraging people to sort waste and manage flexible packaging in a scientific manner.

- Raising Community Awareness about Recycling: Efforts should be made to raise public awareness about the importance of recycling flexible packaging, encouraging people to participate in recycling activities.

- Reusing Packaging: Consumers should be encouraged to reuse good-quality flexible packaging, reducing the need for new packaging.

Flexible packaging has become an indispensable part of modern life. With the advancement of science and technology, flexible packaging is becoming increasingly diverse in materials, structures, and functions, meeting the growing needs of both consumers and businesses. However, along with its many benefits, flexible packaging also poses significant risks to health and the environment. It is crucial to make informed choices and use flexible packaging responsibly, while promoting environmental protection solutions to safeguard human health and the living environment. It is hoped that the information provided in this article will give readers a more comprehensive understanding of flexible packaging, helping them make informed decisions and contribute to building a greener, cleaner, and more sustainable life.