Stretch film

Contact

| Function: | Reinforce and protect goods, prevent risks of falling, tipping, and damage during transportation and storage. |

| Materials: | PE, PP, PVC |

| Size: | Customized. |

| Thickness: | 15 microns to 150 microns. |

| Color: | Transparent or as requested. |

| Features: | Made from virgin PE plastic with good elasticity. |

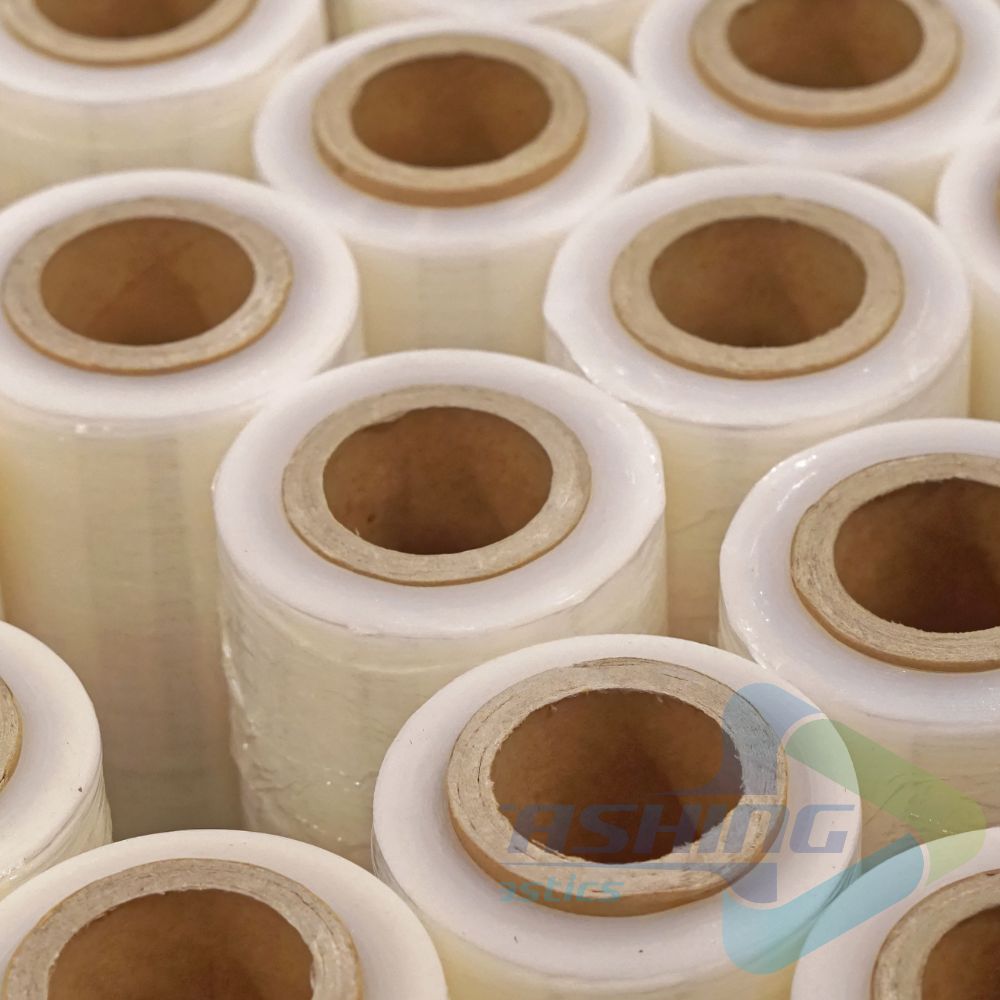

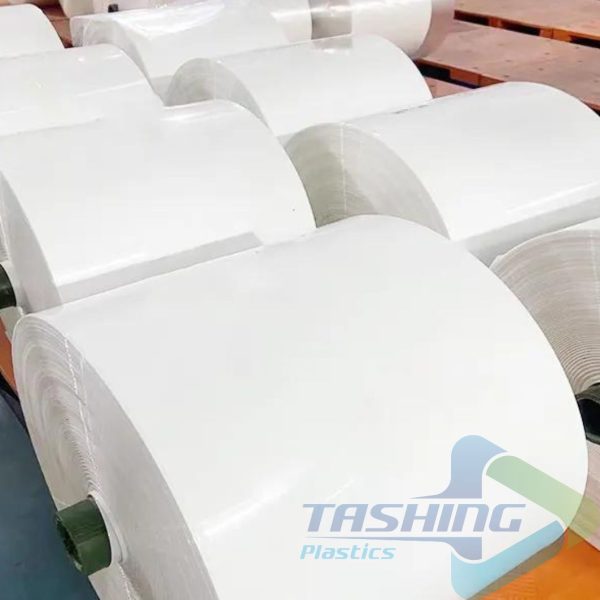

| Packaging: | Roll of 200m, 400m, or as requested. |

- Description

Description

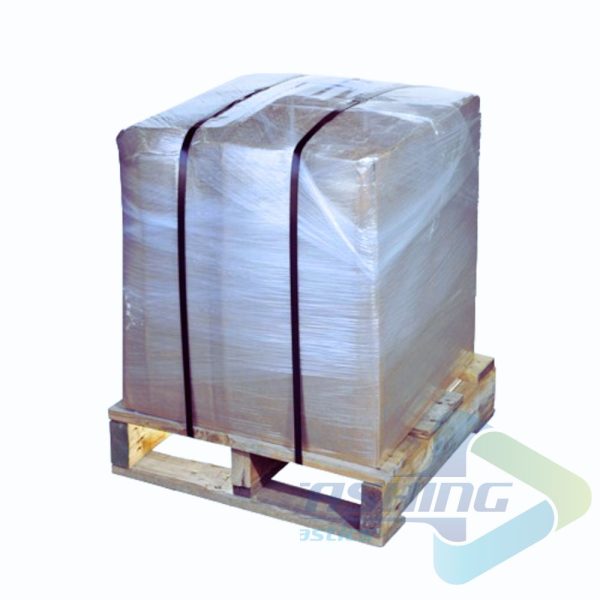

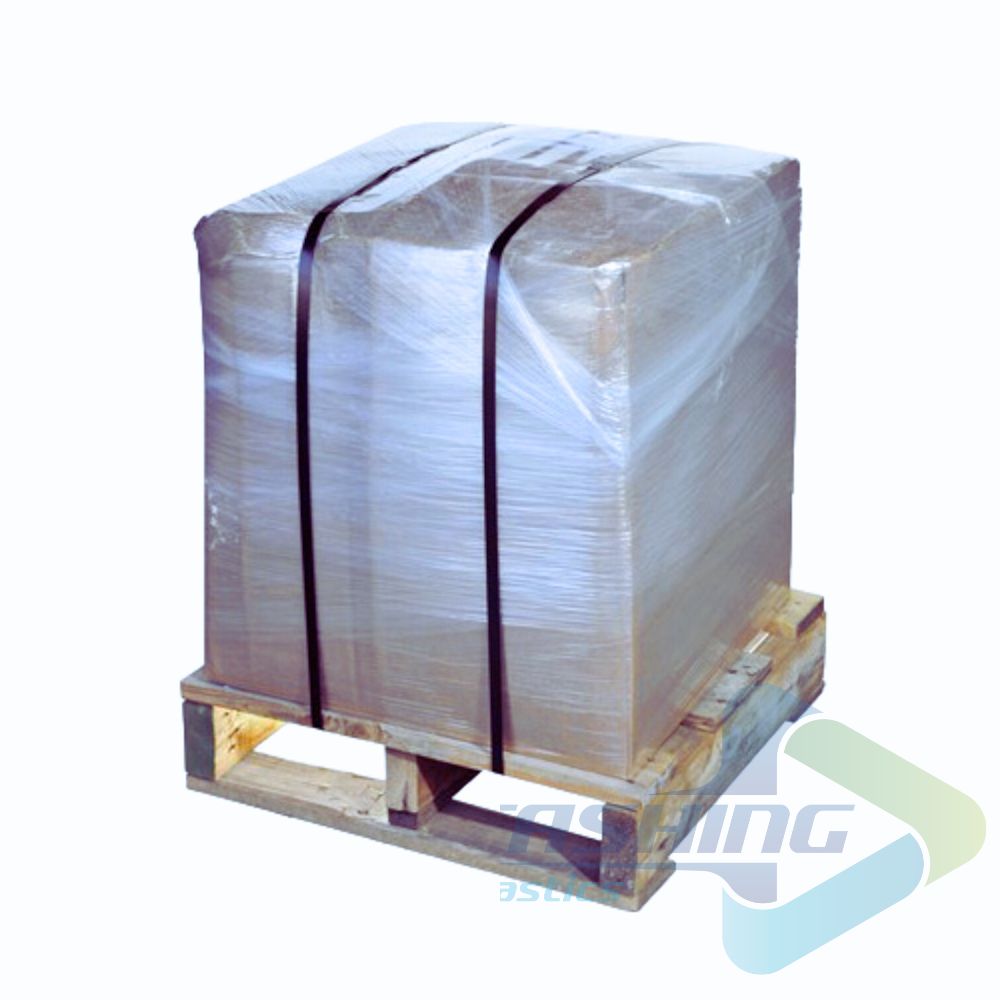

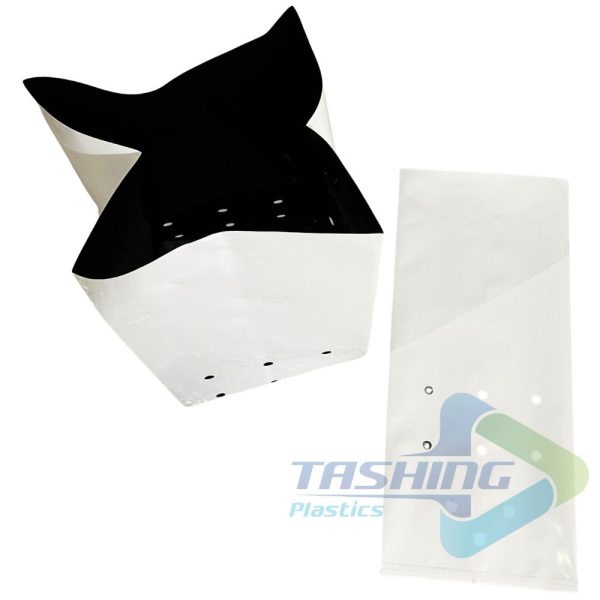

Stretch film and pallet wrapping film play a crucial role in protecting and packaging goods in the industrial, commercial, and transportation sectors. Made from polyethylene (PE) resin, shrink film is characterized by its thinness, toughness, and high stretchability, making it a popular choice for wrapping and securing goods on pallets. The primary function of shrink film is to tightly secure and stabilize goods, preventing the risk of falling, tipping, and damage during transportation and storage.

Material:

Stretch film is primarily produced from polyethylene (PE), PVC, and PP resins, each offering unique properties suitable for different applications.

- PE shrink film is the most popular choice due to its high strength and cost-effectiveness.

- PVC shrink film offers higher strength but comes with a higher cost.

- PP shrink film has high transparency but lower strength compared to PE and PVC.

Technical Specifications:

- Thickness: The thickness of shrink film ranges from 0.01mm to 0.1mm, determining the product’s load-bearing capacity.

- Width: Shrink film is manufactured in various widths, from 50cm to 200cm, to accommodate different cargo sizes.

Functions of Shrink Film and Pallet Wrapping Film:

1. Securing and Stabilizing Goods:

Shrink film is used to wrap and cover goods, pallets, or products to secure and stabilize them during transportation and storage. This helps prevent the risk of falling, tipping, and damage.

2. Protection from External Factors:

Shrink film creates a thin protective layer that provides dust, moisture, and water resistance. This protects goods from environmental factors and preserves product quality.

3. Saving Transportation and Handling Costs:

By tightly securing goods and creating a stable structure, shrink film optimizes the transportation and handling process. This can lead to reduced transportation costs and increased work efficiency.

4. Preventing Peeling and Damage:

Shrink film prevents peeling and damage to products. It adheres tightly to the surface of the goods, keeping components from scratching or peeling during movement.

5. Safe and Efficient Packaging:

Using shrink film provides a safe and efficient way to package goods. It offers a flexible method for packaging various product types, especially those with irregular shapes or different sizes.

6. Non-toxic and Product Preservation:

Shrink film is suitable for packaging products that require quality preservation, such as food, pharmaceuticals, and consumer goods. It helps protect products from the effects of light, air, and moisture.

Wide Applications in Various Industries:

- Manufacturing: Packaging electronics, appliances, and automobiles.

- Commerce: Packaging goods for import and export.

- Transportation: Packaging and transporting supermarket and retail goods.

Tashing Company:

Tashing Company is a leading manufacturer of PE film rolls and pallet wrapping film. Tashing’s products are made from virgin PE resin, ensuring flexibility, high strength, and excellent water resistance. Our products are designed to meet the diverse needs of customers in protecting and packaging goods.

PE film roll is an effective and cost-saving solution for wrapping goods while protecting them from environmental factors such as moisture, dust, and impact. With its excellent stretchability and adhesion, PE film roll helps create a secure and safe protective layer around goods, keeping them stable and tidy during transportation.