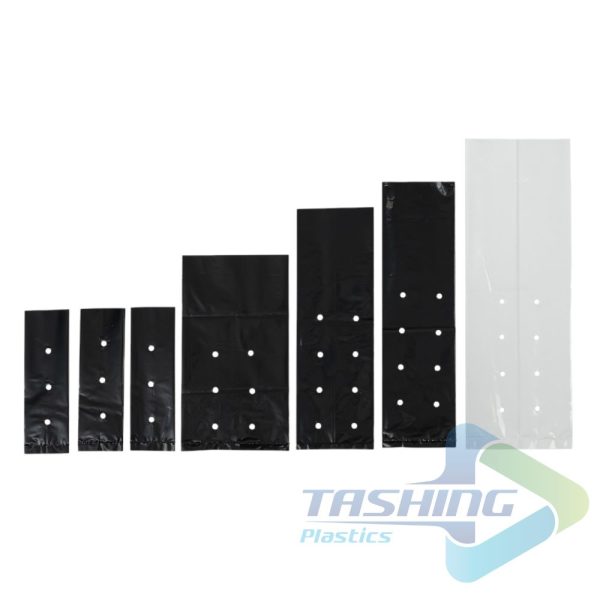

HDPE plastic bags

Contact

- Function: Packaging products, reusable shopping bags, and trash bags

- Material: High-density polyethylene (HDPE)

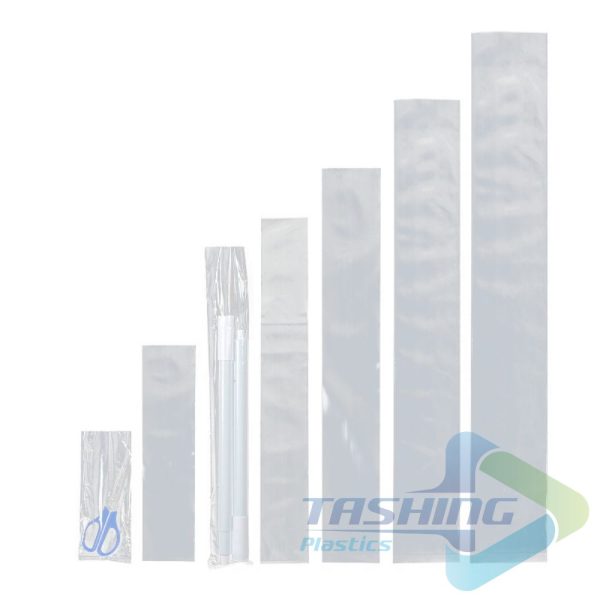

- Sizes: Various sizes from small to large, suitable for different needs

- Thickness: Ranges from 10 microns to 150 microns, suitable and diverse

- Colors: Transparent, white, and many other colors

- Features: Durable, flexible, waterproof, hygienic, recyclable

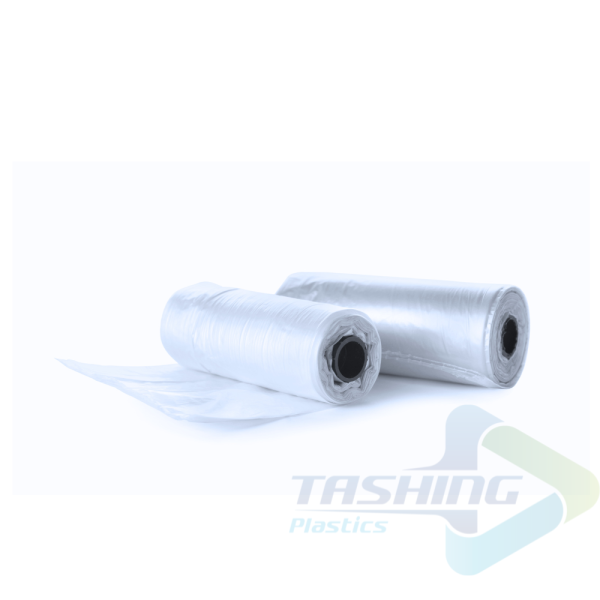

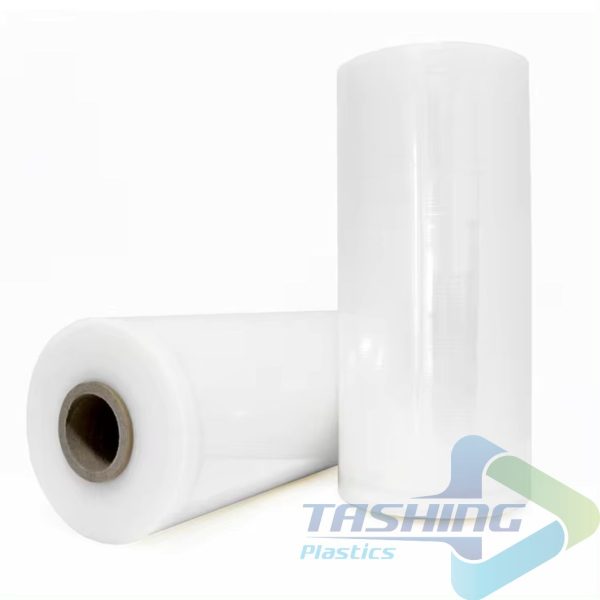

- Packaging: HDPE bags are typically packaged in rolls or retail bags depending on customer needs.

- Description

Description

HDPE plastic bags, derived from high-density polyethylene (HDPE), have become an indispensable part of modern life. Their versatility, strength, and durability have made them a preferred choice for packaging and storing a wide variety of products. This comprehensive guide aims to provide a deep dive into the world of HDPE plastic bags, covering their key characteristics, diverse applications, leading suppliers, and the advantages they offer.

What are HDPE Plastic Bags? Advantages and Applications

HDPE plastic bags are crafted from high-density polyethylene resin, a robust and durable thermoplastic. Their popularity stems from a unique combination of properties that make them suitable for numerous applications.

Understanding HDPE Plastic Bags

High-density polyethylene (HDPE) is a type of polyethylene known for its strength and stiffness. Compared to low-density polyethylene (LDPE), HDPE has a higher density, resulting in a more rigid and durable material. HDPE bags, therefore, provide excellent resistance to tearing, punctures, and impact, making them ideal for packaging and storing heavyweight or sharp items.

Fundamental Characteristics of HDPE Plastic Bags

Apart from durability and water resistance, HDPE plastic bags possess a unique set of characteristics that underpin their wide-ranging applications.

Density and Thickness

The density of HDPE is a crucial factor influencing its strength and stiffness. High-density polyethylene typically ranges in density from 0.94 to 0.97 g/cm³. Greater density leads to a more rigid and robust material. HDPE bags are available in a variety of thicknesses, ranging from a few mils to several mils, depending on the intended application. Thicker bags are better suited for heavier loads and rough handling, while thinner bags offer better flexibility.

Tensile Strength and Impact Resistance

HDPE bags exhibit excellent tensile strength, meaning they can withstand significant pulling forces without tearing. This property is essential for packaging items that might be subjected to high tension, such as ropes, cables, or heavy objects. Additionally, HDPE bags offer good impact resistance, mitigating damage from falls, shocks, or drops.

Heat Resistance and Temperature Tolerance

HDPE retains its structural integrity and strength over a wide temperature range. They are resistant to heat distortion, making them suitable for handling hot products or storing items in high-temperature environments. However, prolonged exposure to very high temperatures may cause degradation.

Chemical Resistance and Compatibility

HDPE exhibits reasonable resistance to a variety of chemicals, including acids, bases, and solvents. This property is invaluable in industries dealing with corrosive materials. Nevertheless, it is crucial to select HDPE bags compatible with the specific chemicals being packaged to prevent breakdown or contamination.

UV Resistance and Color Stability

HDPE bags possess moderate UV resistance, minimizing detrimental effects from prolonged exposure to sunlight. However, extended sun exposure can cause discoloration and degradation over time. This factor becomes particularly relevant when using HDPE bags for outdoor storage or transportation.

Physical Properties Summary

| Property | Description |

|---|---|

| Density | Typically ranges from 0.94 to 0.97 g/cm³ |

| Thickness | Varies based on application, ranging from a few mils to several mils |

| Tensile Strength | Excellent, resisting significant pulling forces |

| Impact Resistance | Good, mitigating damage from falls or shocks |

| Heat Resistance | Resists heat distortion and withstands moderate temperatures |

| Chemical Resistance | Exhibit good resistance to various chemicals |

| UV Resistance | Moderate, minimizing discoloration and degradation from sunlight |

Common Applications of HDPE Plastic Bags

HDPE plastic bags serve a wide range of purposes, particularly in industries where strength, durability, and moisture resistance are paramount.

Food Packaging

- Produce Packaging: Fruits and vegetables are often packed in HDPE bags to preserve their freshness and prevent spoilage. Their impermeability to moisture and oxygen helps retain moisture and reduce bacterial growth.

- Grain and Cereal Packaging: HDPE bags are ideal for storing grains, cereals, flours, and other dry goods because they prevent moisture absorption and infestation.

- Snack Food Packaging: Snacks and confectionery items are often packaged in HDPE bags to protect them from moisture, contamination, and damage.

Industrial Packaging

- Chemical Packaging: HDPE bags are used to store and transport various industrial chemicals, including acids, bases, and solvents. Their chemical resistance ensures the safe handling of corrosive substances.

- Construction Materials Packaging: HDPE bags are widely used for packaging sand, gravel, cement, and other construction materials. Their strength and durability enable safe and efficient handling during construction projects.

- Agricultural Products Packaging: HDPE bags are used for packing fertilizers, seeds, animal feed, and other agricultural products. Their moisture resistance and strength make them ideal for handling these sensitive materials.

Retail Packaging

- Shopping and Carry Bags: HDPE bags are commonly used as shopping and carry bags due to their convenience, durability, and affordability. Their lightweight nature makes them easy to handle, and their water resistance helps protect purchases from rain or spills.

- Merchandise Packaging: HDPE bags are used to package a wide variety of retail items, from clothing and accessories to electronics and toys. Their strength and flexibility allow for secure and attractive packaging.

- Product Storage and Organization: HDPE bags can also be used for organizing and storing items in retail settings, such as bulk goods, supplies, or accessories.

Waste Management

- Garbage Bags: HDPE bags are a popular choice for garbage bags due to their strength and resistance to leaks. Their durability ensures proper and secure containment of waste materials.

- Recyclable Waste Collection: HDPE bags can be used for collecting recyclable materials, ensuring their separation from general waste for proper recycling processes.

HDPE Plastic Bags in Ho Chi Minh City

Ho Chi Minh City (HCMC), Vietnam’s largest city, is a major hub for the production and distribution of HDPE plastic bags. The city’s growing industrial sector, coupled with a large population, creates a significant demand for these versatile packaging solutions.

Key Manufacturers and Suppliers

HCMC boasts a thriving industry of HDPE plastic bag manufacturers, including both large-scale producers and smaller, specialized suppliers. These manufacturers cater to diverse industries, including food, manufacturing, agriculture, and retail.

Market Trends and Growth Potential

The demand for HDPE plastic bags in HCMC is expected to continue growing in the coming years, driven by factors such as:

- Expanding Industrial Sector: The city’s industrialization is leading to increased demand for packaging materials like HDPE bags.

- Rising Consumer Demand: A growing population and rising disposable incomes have fueled demand for consumer products and packaging.

- E-commerce Boom: The rapid growth of e-commerce has increased the need for suitable packaging materials for online purchases, making HDPE bags a popular choice.

- Government Initiatives: Initiatives focused on waste management and recycling have created opportunities for manufacturers of HDPE bags, which are recyclable and environmentally friendly.

Industry Challenges and Opportunities

Despite the promising growth potential, the HDPE plastic bag industry in HCMC faces several challenges, including:

- Competition: The market is highly competitive, with numerous manufacturers vying for market share.

- Fluctuating Raw Material Prices: The cost of HDPE resin fluctuates, impacting production costs and profitability.

Despite these challenges, the industry presents a range of opportunities for innovation and growth:

- Technology Adoption: Manufacturers can leverage advancements in technology to enhance production efficiency and sustainability.

- Product Differentiation: Offering specialized HDPE bag solutions for specific industries or applications can help manufacturers stand out in a competitive market.

- Sustainability Initiatives: Focusing on eco-friendly production practices, using recycled content, and promoting responsible disposal can attract environmentally conscious consumers.

HDPE Plastic Bags from Di Dai Hung

Di Dai Hung, a leading manufacturer of HDPE plastic bags in HCMC, sets the standard for quality, innovation, and customer satisfaction. The company is renowned for its commitment to providing high-performance, reliable, and durable HDPE bags that meet the needs of a wide range of industries.

A Focus on Quality and Reliability

Di Dai Hung prioritizes quality in every aspect of its operations, from the selection of raw materials to production processes and final product inspection. The company uses only high-grade HDPE resin and employs stringent quality control measures to ensure consistent product quality and reliability.

Diverse Product Portfolio for All Needs

Di Dai Hung offers a comprehensive range of HDPE plastic bags designed to meet the specific requirements of various industries:

- Food Packaging Bags: Custom sizes and thicknesses for different food products, ensuring freshness and safety.

- Industrial Packaging Bags: Heavy-duty bags for transporting and storing bulk materials, chemicals, and industrial components.

- Agricultural Packaging Bags: Durable bags for packing fertilizers, seeds, animal feed, and other agricultural products.

- Retail Packaging Bags: Lightweight, yet strong bags for shopping, carrying merchandise, and organizing products.

- Waste Management Bags: Durable and leak-resistant bags for collecting and transporting waste materials.

Di Dai Hung also provides custom bag solutions tailored to specific customer requirements, including:

- Size and Dimension Customization: Bags can be designed to fit specific product sizes and shapes.

- Printing and Branding: Custom printing options for logos, branding elements, and product information.

- Material Options: Different HDPE grades and thicknesses can be selected to optimize strength, flexibility, and cost-effectiveness.

- Closure Options: Various closure options, including heat sealing, fold-over, and drawstring, can be implemented to secure bag contents.

Commitment to Customer Satisfaction

Di Dai Hung is dedicated to providing excellent customer service and support. The company’s experienced team works closely with clients to understand their needs and develop solutions that meet their unique requirements. Di Dai Hung also offers:

- Competitive Pricing: Committed to offering competitive pricing on all its products, ensuring value for money for customers.

- Fast and Efficient Delivery: Timely and reliable delivery services to meet customer deadlines and minimize downtime.

- Excellent After-Sales Support: Providing ongoing support and assistance to ensure customer satisfaction.

Benefits of Choosing Di Dai Hung

Choosing Di Dai Hung as your HDPE plastic bag supplier offers significant advantages:

- High-Quality Products: Exceptional quality and durability, ensuring reliable protection for goods.

- Wide Product Range: Extensive selection of HDPE bags catering to diverse industries and needs.

- Custom Solutions: Flexible customization options to meet specific requirements.

- Competitive Pricing: Affordable prices without compromising quality.

- Excellent Customer Service: Dedicated support team ensuring seamless interactions and satisfaction.

Calculating the Weight of PE Film

PCalculating the weight of PE film is crucial in both its manufacturing and usage processes. Below are two common methods to determine the weight of PE film.

- Using Formula: When calculating the weight of a specific quantity of PE film bags, using a formula is a popular choice. The formula below helps accurately calculate the weight:Weight of 1 PE film bag = Length × Width × Thickness × Density of PEFor example, if you want to calculate the weight of a PE film bag with dimensions of 1m x 0.5m and a thickness of 100 micrometers, using HDPE (density approximately 0.94 – 0.96 kg/m³), you can apply the formula as follows:Weight of PE film bag = 1m × 0.5m × 0.0001m × 940 kg/m³ ≈ 0.047 kg

Hence, Number of PE films per kg = 1 / 0.047 = 21 films/kg

Below is an example table of five different types of Polyethylene (PE) and their corresponding densities:

| Type of PE | Density (g/cm³) | Density (kg/m³) |

| Homopolymer | 0.90 – 0.92 | 900 – 920 |

| Copolymer | 0.91 – 0.94 | 910 – 940 |

| HDPE | 0.94 – 0.96 | 940 – 960 |

| LDPE | 0.91 – 0.93 | 910 – 930 |

| LLDPE | 0.92 – 0.94 | 920 – 940 |

This provides a comprehensive overview of how to calculate the weight of PE film and the densities of various types of Polyethylene.

Conclusion

HDPE plastic bags continue to play a significant role in various industries, from food packaging to manufacturing, agriculture, and waste management. Their strength, durability, moisture resistance, and recyclability make them an environmentally responsible and reliable choice. Di Dai Hung, a leading provider of HDPE plastic bags in Ho Chi Minh City, offers a wide range of high-quality, customizable solutions that meet the diverse needs of its clientele. Choosing Di Dai Hung ensures access to high-performance bags, competitive pricing, and excellent customer service, making them a trusted partner for businesses seeking reliable HDPE plastic bag solutions.