Automatic Packaging Film Rolls

Contact

| Functionality: | Used in automatic packaging machines, vertical packaging machines, horizontal packaging machines, shrink wrap machines, etc. |

| Material: | LDPE (Low-Density Polyethylene) |

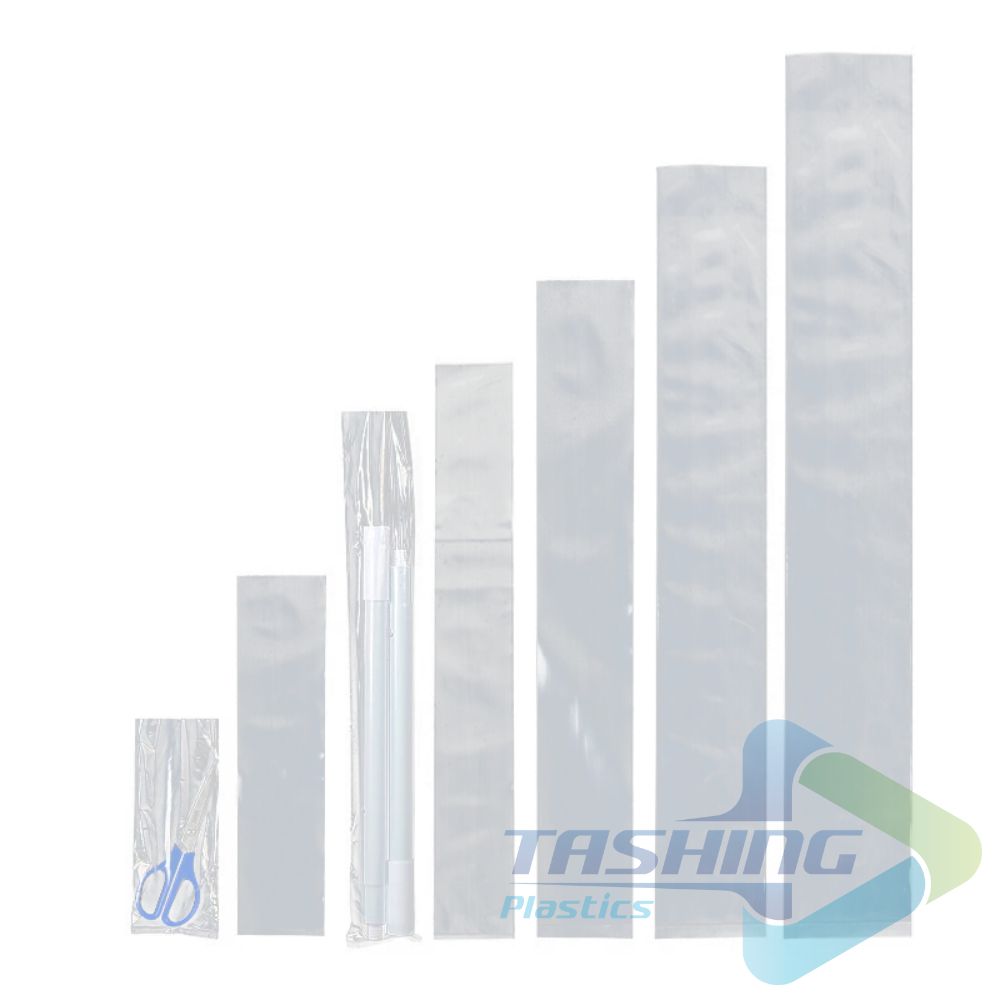

| Size: | Diverse, customizable according to customer requirements |

| Thickness: | Options range from 20 to 160 microns |

| Color: | Clear white, opaque white, or customized as per request |

| Features: | Uniform film size and roll thickness, moisture-resistant, dust-resistant, high durability, and customizable |

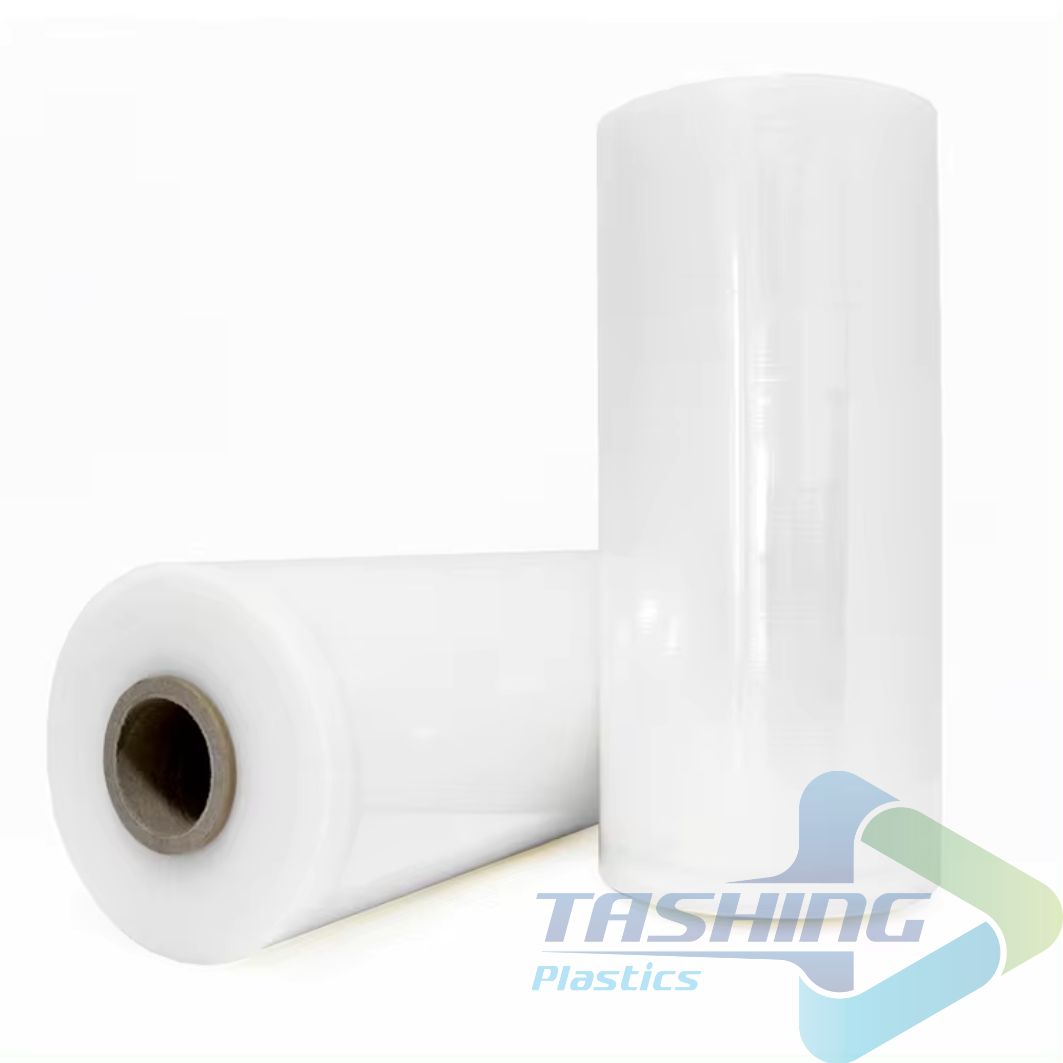

| Packaging: | Packaged in rolls as per requirements |

- Description

Description

Automatic packaging film rolls are a type of packaging material made from polyethylene (PE) resin. They are typically produced as rolls that can be easily integrated into automated packaging machinery, facilitating fast, precise, and efficient packaging processes. PE films possess qualities such as high durability, moisture and dust resistance, and can be customized in thickness, size, and color to meet specific product and machine requirements.

Characteristics of Films for Automatic Packaging

PE film material is made from PE resin, a flexible, lightweight plastic with high durability. The thickness of PE films can be adjusted according to product durability and aesthetic requirements. The roll dimensions can also be customized to match the size of the product being packaged and the machinery used. PE films are usually clear or milky white, but they can be produced in various colors upon request. PE film offers moisture resistance, waterproofing, and protection against dust, impacts, and other environmental factors.

Requirements for PE Rolls Used in Automatic Packaging

To ensure effectiveness in the automated packaging process, PE film rolls need to meet the following requirements:

- Thickness: Consistent thickness ensures stable packaging, preventing tearing or inadequate protection due to thin spots. Appropriate thickness is chosen based on the weight, size, and nature of the product.

- Size: The width of the PE film must suit the packaging machine and product dimensions. The length should be sufficient for packaging a designated number of products. The roll’s core diameter must match the machine’s spool.

Applications of PE Film in Automatic Packaging

PE film applications in automated packaging are diverse. In the food industry, PE film is used to package items such as snacks, instant noodles, rice, and grains. In consumer goods, PE film is applied for household items, office supplies, and cosmetics. In industrial sectors, PE film is used for packaging electronic components, automotive parts, and chemical products.

Advantages of Using PE Film in Automatic Packaging

Using PE film in automatic packaging offers several benefits, including increased productivity thanks to a fast and continuous packaging process. PE film protects products from dust and bacteria, ensuring food safety. Additionally, PE film saves on labor and packaging material costs and allows for versatile applications across a wide range of products.

Tashing Automatic Packaging Film Rolls

Tashing Company produces high-quality automatic packaging film rolls that meet strict standards for durability, aesthetics, and efficiency in the packaging process. Tashing’s PE film products provide optimal protection for goods, making packaging easy and cost-effective for businesses.

Conclusion

PE film rolls play a crucial role in the automatic packaging industry due to their exceptional properties such as high durability, moisture and dust resistance, aesthetic appeal, and flexibility in size and color. The use of PE film not only boosts production efficiency but also ensures product safety, reduces costs, and enhances business effectiveness. With a commitment to quality, Tashing Company is a reliable partner for businesses seeking efficient and optimal packaging solutions. Tashing’s PE film rolls meet stringent standards and offer practical benefits, contributing to the sustainable development of the packaging industry