Buy Anti-static LDPE bags in Vietnam

Contact

- Function: Store electronic components, prevent static buildup, protect from electrostatic damage.

- Material: PE (Polyethylene)

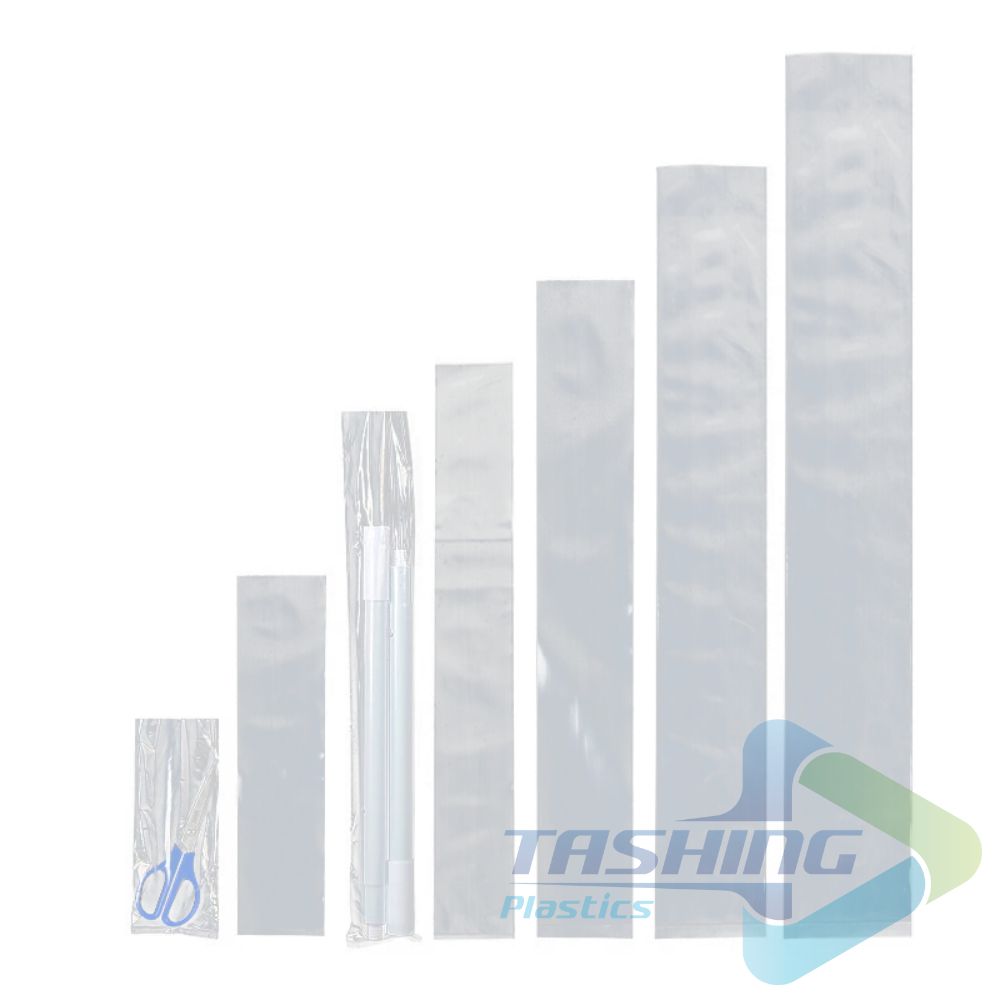

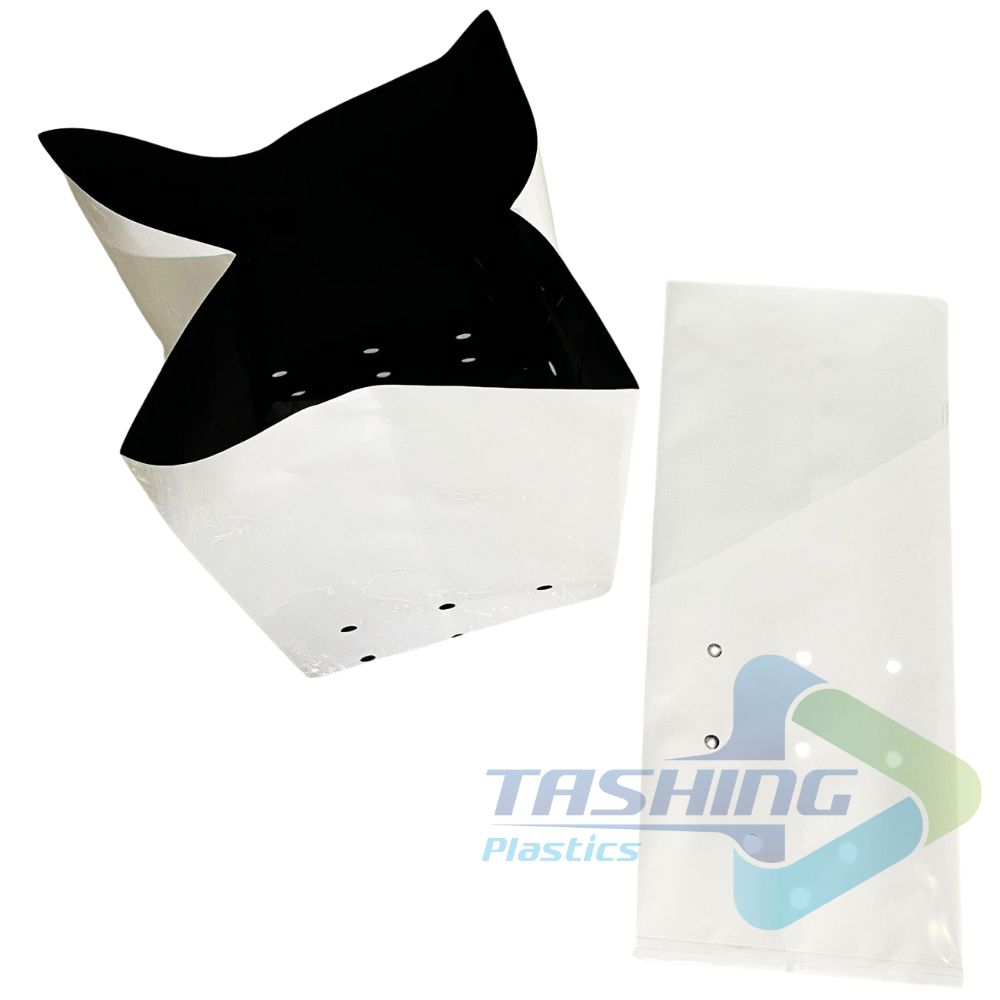

- Sizes: 10×15 cm, 20×25 cm, 40×50 cm, or as per request.

- Thickness: 30 to 150 microns.

- Colors: Customizable.

- Features: Electrical conductivity ranges from 10^9 to 10^11 ohms.

- Packaging: 10kg, 25kg per bundle, or custom.

- Description

Description

In the realm of electronics, static electricity poses a significant threat, capable of damaging sensitive components and disrupting delicate circuits. Anti-static LDPE bags, designed specifically for this purpose, offer a crucial layer of protection, safeguarding electronic devices from the hazards of electrostatic discharge (ESD). These specialized bags are widely used in industries such as electronics manufacturing, assembly, and logistics, playing a vital role in ensuring the integrity and functionality of sensitive electronics.

Introduction

Anti-static LDPE bags are an indispensable tool in the electronics industry, serving as a vital safeguard against the damaging effects of static electricity. These specialized bags, made from low-density polyethylene (LDPE) with added anti-static properties, act as a barrier, preventing the build-up and discharge of static charges, protecting sensitive electronic components from potential damage. The importance of anti-static LDPE bags lies in their ability to mitigate the risks associated with ESD, a phenomenon that can severely impact the performance and lifespan of electronic devices.

What are Anti-static LDPE Bags?

Anti-static LDPE bags, often referred to as ESD bags or static-dissipative bags, are meticulously engineered to control the accumulation and dissipation of static charges. Unlike standard LDPE bags, which can easily attract and retain static electricity, anti-static bags possess unique characteristics that promote static charge dissipation.

Anti-static Properties

The key to the effectiveness of anti-static LDPE bags lies in the incorporation of special anti-static additives during the manufacturing process. These additives, typically in the form of conductive or dissipative materials, impart the desired static-dissipative properties to the LDPE. These additives create a pathway for static charges to flow through the material, preventing them from accumulating on the surface of the bag.

How Anti-static LDPE Bags Differ from Standard LDPE Bags

- Static Dissipative Properties: Unlike regular LDPE bags, which can readily attract and hold static charges, anti-static LDPE bags are designed to dissipate static electricity quickly and efficiently.

- Material Composition: The main difference between the two types of bags is the addition of anti-static additives to the LDPE material in anti-static bags. These additives enhance the surface conductivity of the bag, enabling the rapid dissipation of static charges.

Different Types of Anti-static LDPE Bags

The world of anti-static LDPE bags offers a range of specialized variations to meet specific needs, each tailored to different applications and requirements. Some common types include:

- Pink anti-static LDPE bags: Pink is often used to indicate anti-static properties in the electronics industry. These bags are ideal for storing and transporting sensitive electronic components.

- Clear anti-static LDPE bags: These bags offer excellent visibility, allowing for easy identification of the contents without needing to open the bag. Clear anti-static bags are preferred when transparency is essential.

- Anti-static LDPE bags with a zip lock closure: Zip lock closures provide a secure and convenient way to seal the bag and protect the contents from dust, moisture, and static discharge.

Benefits of Using Anti-static LDPE Bags

The use of anti-static LDPE bags offers numerous advantages, particularly in protecting sensitive electronic components from the hazards of static electricity.

Protection Against Electrostatic Discharge (ESD)

Anti-static bags are a cornerstone of ESD control. They act as a protective barrier, preventing the build-up of static charges on electronic components, thereby minimizing the risk of ESD damage. ESD can lead to a range of issues, including:

- Component Failure: Static discharge can damage sensitive electronic components, leading to malfunctions or complete failure.

- Circuit Damage: ESD can cause shorts or opens in circuits, disrupting the flow of electricity and impairing device function.

- Data Loss: Static discharge can corrupt data stored on electronic devices, potentially resulting in data loss or corruption.

Precaution Against Damage During Transportation and Storage

During transportation or storage, electronic devices are exposed to various environmental factors that can contribute to static charge build-up. Anti-static LDPE bags provide a robust layer of protection against these factors, preventing the accumulation of static charges that could potentially damage sensitive components.

Compliance with Industry Standards

The electronics industry adheres to stringent standards for electrostatic discharge (ESD) control, including standards for packaging materials. Anti-static LDPE bags play a critical role in ensuring compliance with these standards.

Applications of Anti-static LDPE Bags

Anti-static LDPE bags have widespread applications across diverse industries that handle sensitive electronic components.

Electronics Manufacturing and Assembly

Within electronics manufacturing and assembly facilities, these bags are essential for storing, transporting, and protecting delicate electronic components, printed circuit boards, and other static-sensitive items.

- Component Packaging: They are used to individually package components like transistors, microchips, capacitors, and resistors, protecting them from damage during handling and storage.

- Circuit Board Protection: Used to package and transport assembled circuit boards, safeguarding them from ESD damage during transit.

- Component Protection During Production: Often used on assembly lines, they protect components from static discharge during production processes

Other Relevant Industries:

Beyond electronics manufacturing, anti-static LDPE bags find application in various industries that deal with sensitive electronics, including:

- Telecommunications: Used for packaging and transporting sensitive electronic equipment.

- Medical Devices: Used to package and transport medical devices with electronic components.

- Aerospace and Defense: Used to protect sensitive electronic components in aerospace and defense applications.

- Data Storage: Used to package hard drives, SSDs, and other data storage devices, protecting them from ESD damage during handling and storage.

Features to Look for in Anti-static LDPE Bags

When selecting anti-static LDPE bags, certain features are crucial to ensure optimal protection for electronic components.

Thickness and Durability

The thickness of the material is directly related to the bag’s strength and its ability to withstand stress during handling and shipping. A thicker bag offers greater protection, especially for fragile components or those requiring additional cushioning.

Closure Mechanisms

Anti-static LDPE bags can feature various closure mechanisms, each offering specific advantages:

- Zip Lock Closures: Zip lock closures are a popular choice for securing anti-static LDPE bags. They provide a tight seal, protecting the contents from dust, moisture, and static discharge.

- Heat Sealing: Heat sealing is a reliable method for sealing anti-static LDPE bags. Heat is applied to melt the material, creating a strong and tamper-resistant seal.

- Tie Closures: Tie closures are simple and effective, using a string or ribbon to secure the bag. They are often used for lighter components or when a quick seal is needed.

Transparency

The transparency of the anti-static LDPE bag is a critical feature. Clear or translucent bags allow for easy identification of the contents without needing to open the bag. This is particularly useful for inventory control and logistics.

Proper Handling and Storage of Anti-static LDPE Bags

To achieve optimal protection, it’s essential to follow proper handling and storage guidelines for these bags.

Storage Guidelines

- Store in a Clean, Dry Environment: These bags should be stored in a clean, dry environment. Moisture and dust can compromise their effectiveness, reducing their ability to dissipate static charges.

- Avoid Temperature Extremes: Expose them to extreme temperatures. High temperatures can degrade the anti-static properties of the bags, while low temperatures can make the material brittle and prone to tears.

- Ensure Proper Ventilation: Store them in a well-ventilated area to prevent the build-up of humidity, which can attract static charges.

Handling Techniques

- Ground Yourself: Before handling anti-static LDPE bags, it’s crucial to ground yourself by touching a grounded surface. This diverts static charges away from your body, preventing the transfer of static electricity to the bag and its contents.

- Use Grounded Work Surfaces: Work surfaces should be properly grounded to create a conductive path for static charges. ESD-safe work mats are essential for minimizing static buildup.

- Minimize Movement: Rapid movements generate static electricity. Handle antistatic LDPE bags slowly and carefully to reduce the risk of static buildup.

How to Test the Effectiveness of Anti-static LDPE Bags

Regular testing is essential to ensure the ongoing effectiveness of anti-static LDPE bags, guaranteeing continued protection for sensitive electronic components.

Testing Methods

- Surface Resistance Testing: This method involves measuring the surface resistance of the bag, which indicates its ability to dissipate static charges. A low surface resistance signifies good anti-static properties.

- Static Decay Time Testing: This test measures the time it takes for a static charge to dissipate on the surface of the bag. A shorter decay time indicates a higher level of static dissipation.

- Visual Inspection: Regularly inspect anti-static LDPE bags for signs of wear, tears, or other damage. Damaged bags may compromise their ability to effectively dissipate static charges.

Importance of Testing

- Quality Assurance: Testing anti-static LDPE bags ensures their effectiveness in protecting electronic components from ESD damage.

- Preventative Maintenance: Regular testing allows for the identification of bags that have lost their effectiveness due to wear or damage. This prevents the use of compromised bags that could expose sensitive electronics to ESD hazards.

- Compliance with Standards: In industries with strict ESD control regulations, regular testing of anti-static packaging materials is crucial for compliance with industry standards.

Buy Antistatic LDPE Bags in Vietnam

When seeking anti-static LDPE bags in Vietnam, it’s crucial to choose a reputable supplier that prioritizes quality, reliability, and customer satisfaction.

Factors to Consider When Choosing a Supplier

- Quality of Materials: Ensure the supplier uses high-quality LDPE material with proven anti-static properties.

- Manufacturing Expertise: Select a supplier with extensive experience in plastic packaging manufacturing, particularly specializing in anti-static LDPE bags.

- Compliance with Standards: Verify that the supplier’s products meet relevant industry standards, such as IEC 61340-5-1, ensuring compliance with ESD control regulations.

- Customer Service: Choose a supplier with exceptional customer service, readily providing technical support, product information, and assistance with order fulfillment.

Di Dai Hung Co., Ltd. – Tashing Plastic

Di Dai Hung Co., Ltd., also known as Tashing Plastic, is a leading manufacturer and supplier of anti-static LDPE bags in Vietnam. The company boasts a long history of expertise in plastic packaging, with a commitment to quality and customer satisfaction.

Why Choose Tashing Plastic?

Experience and Expertise: Tashing Plastic has extensive experience in plastic packaging manufacturing, specializing in anti-static solutions.

- Quality Materials: The company uses high-quality LDPE material with proven anti-static properties, ensuring the effectiveness of its bags in protecting sensitive electronics.

- Customizable Solutions: Tashing Plastic offers customizable options, catering to diverse specifications and requirements.

- Competitive Pricing: The company provides competitive pricing, ensuring value for money for its customers.

Notes

- ESD Control Programs: Integrate the use of anti-static bags into comprehensive ESD control programs. These programs should include training personnel on proper handling procedures, specifying appropriate work surfaces and grounding techniques, and establishing routine testing protocols for anti-static materials.

- Environmental Considerations: Consider the environmental impact of plastic bags. Explore the use of recycled or biodegradable LDPE materials to minimize the plastic footprint.

Mistakes to Avoid

To maximize the protective benefits of these bags, it’s crucial to avoid common mistakes that can compromise their effectiveness.

- Improper Grounding: Failure to properly ground yourself before handling increases the risk of transferring static electricity to the bag and its contents.

- Incorrect Storage Conditions: Storing in unclean or humid environments can attract static charges and reduce their effectiveness. Inappropriate temperature fluctuations can also degrade the material’s properties.

- Overuse: Using for non-static-sensitive items waste resources. Focus on using where they are truly needed, protecting sensitive electronic components from ESD.

Neglecting Regular Testing: Fail to test regularly, potentially exposing sensitive electronics to unnecessary risks.

Frequently Asked Questions

What is the difference between anti-static and static shielding bags?

Anti-static bags dissipate static charges by providing a pathway for them to flow through the material. Static shielding bags, on the other hand, block static charges from reaching the contents by creating a barrier of conductive material.

Can anti-static LDPE bags be reused?

These bags can be reused multiple times as long as they remain in good condition. However, inspecting them for signs of wear and tear before reuse is essential to ensure continued effectiveness.

Are there specific disposal methods for anti-static LDPE bags?

Their disposal should adhere to local regulations and recycling guidelines. In many regions, these bags can be recycled with other plastic materials, contributing to sustainable waste management practices.

Conclusion

Anti-static LDPE bags are essential for shielding sensitive electronic components from static electricity. These specialized bags are crucial in electronics manufacturing, assembly, transportation, and storage, ensuring the integrity and functionality of delicate electronic devices. Di Dai Hung Co., Ltd., also known as Tashing Plastic, is a top manufacturer and supplier of these bags in Vietnam, providing high-quality products and reliable service. Partnering with a trusted supplier and following proper handling and storage guidelines maximizes the protective benefits, safeguarding electronic components from ESD damage.