PE Plastic Bags Available in Vietnam

Contact

| Function: | Used for storing food, packaging goods, industrial use, and daily life. |

| Materials: | LDPE (Soft, flexible, transparent, heat-resistant) HDPE (Hard, durable, chemical-resistant) LLDPE (Soft, transparent, heat-resistant) |

| Sizes: | Available in various sizes from small to large, customizable upon request. |

| Examples of products: | Supermarket plastic bags: 26cm x 40cm, 30cm x 45cm, 35cm x 50cm Trash bags: 50cm x 100cm, 60cm x 120cm, 80cm x 150cm Ziplock bags: 10cm x 15cm, 15cm x 20cm, 20cm x 30cm |

| Thickness: | Ranges from 10 Micrometers to 160 Micrometers. |

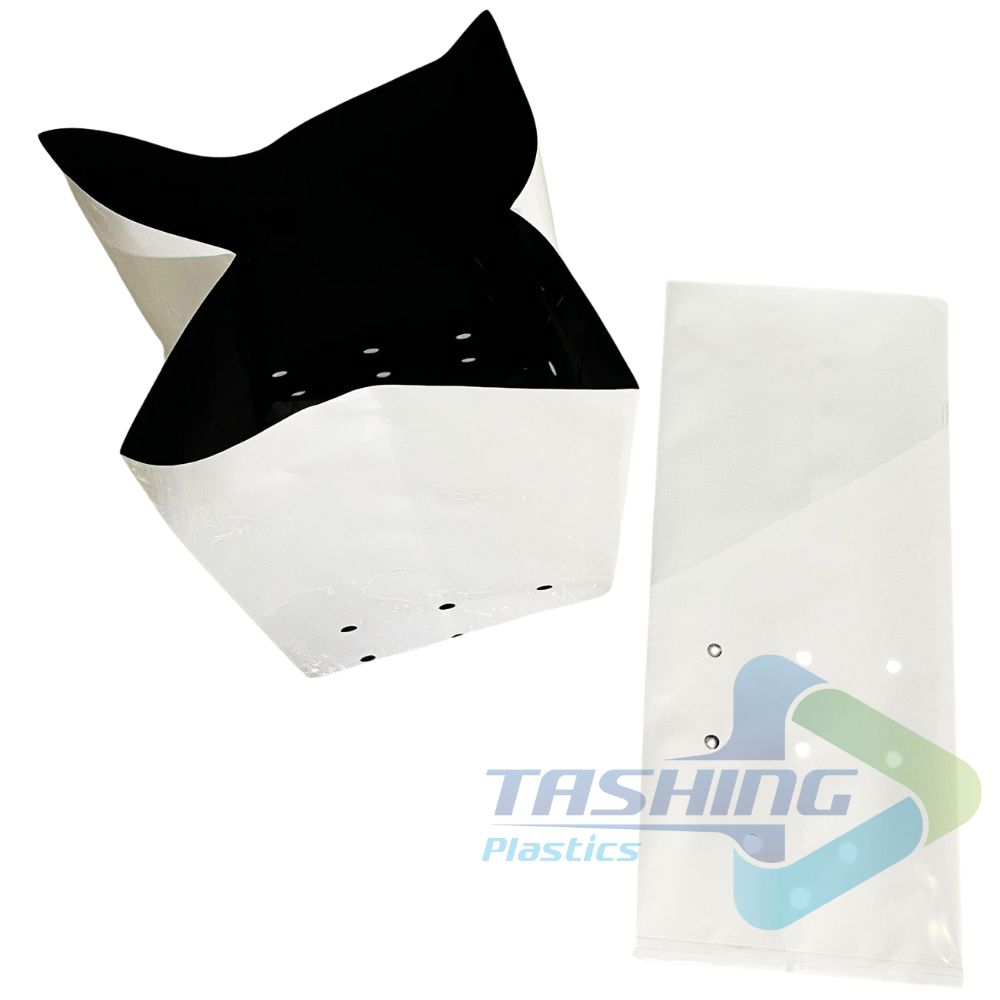

| Colors: | Available in a variety such as white, black, green, blue, customizable as per requirements. |

| Features: | Soft, flexible, waterproof, heat-resistant, easy to package and transport, cost-effective. |

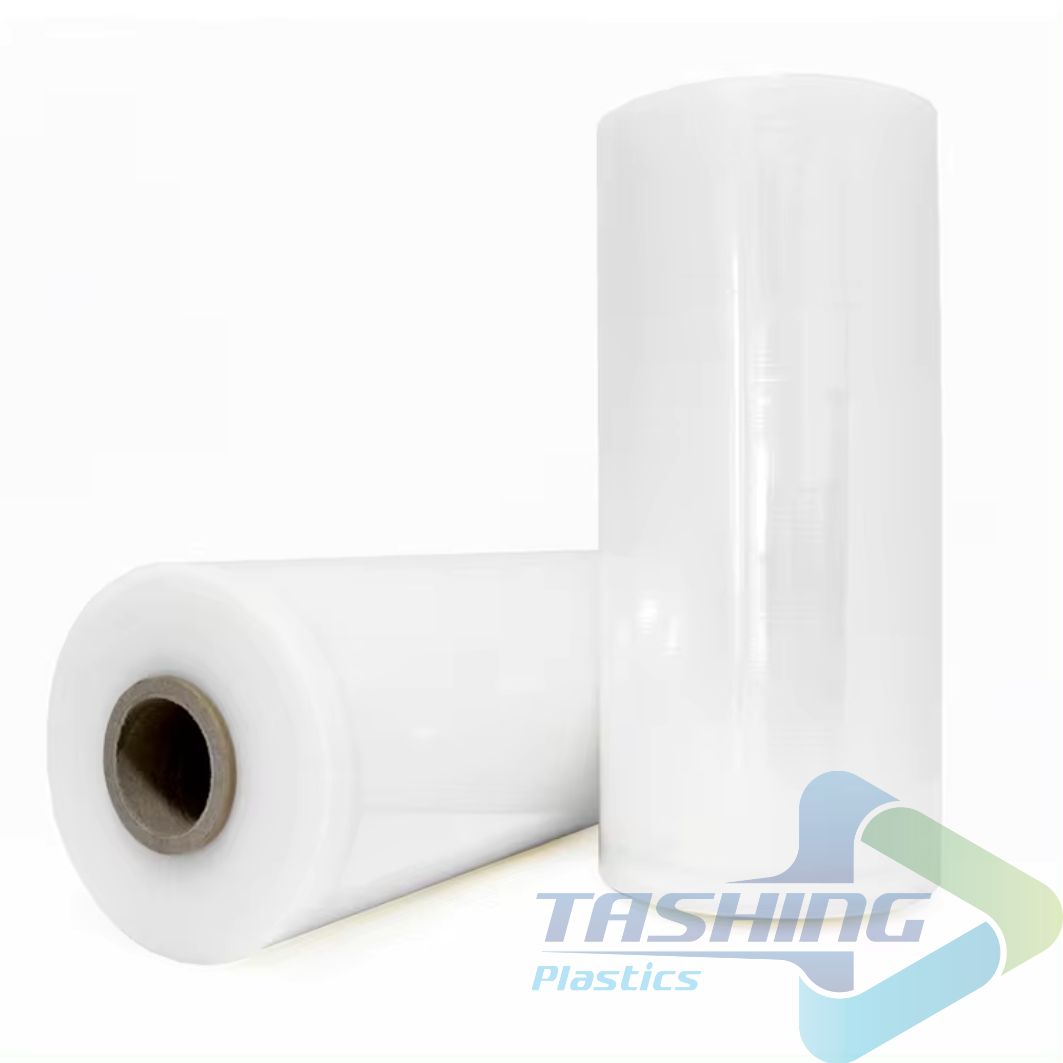

| Packaging: | Usually in bundles or rolls, depending on size and thickness. |

- Description

Description

PE plastic bags, commonly known as polyethylene bags, are a ubiquitous packaging material found across diverse industries. Their versatility, affordability, and durability make them an ideal choice for various applications, ranging from groceries to industrial products. This article provides an in-depth exploration of PE plastic bags, delving into their properties, advantages, applications, and manufacturing process. We will also examine the thriving PE bag market in Ho Chi Minh city, highlighting the prominent role of companies like Di Dai Hung Co., Ltd in meeting the region’s packaging needs.

|  |  |

|  |  |

Description

PE Plastic Bags: What Are They?

PE plastic bags are manufactured from polyethylene (PE), a common thermoplastic polymer renowned for its flexibility, strength, and water resistance. PE is derived from the polymerization of ethylene, a colorless gas obtained from petroleum or natural gas. The resulting plastic is remarkably versatile, readily molded into various forms and readily recycled, making it a sustainable material for packaging.

Properties of PE Plastic Bags

PE plastic bags exhibit a unique set of properties that contribute to their widespread use. These characteristics can be broadly categorized into physical and chemical properties, as well as mechanical properties.

Physical and Chemical Properties

- Safety: PE bags are generally safe for food and other products, as polyethylene does not contain harmful chemicals. The production process usually incorporates virgin polyethylene, ensuring the absence of toxic materials.

- Temperature Resistance: PE bags exhibit good resistance to low temperatures. This makes them suitable for packaging frozen foods or products that require storage in cold environments.

- Chemical Stability: PE bags possess high chemical stability, making them resistant to degradation by commonly used detergents and cleaning agents.

Mechanical Properties

- Flexibility: One of the most notable characteristics of PE bags is their flexibility. This property allows them to be easily folded, compressed, and filled with various products without tearing.

- Durability: PE bags are relatively strong and resilient. They can withstand considerable weight and resist puncture, ensuring the safe transport and storage of goods.

- Water Resistance: PE bags offer excellent water resistance, making them suitable for packaging wet or moist products without compromising their integrity.

- Barrier Properties: The polyethylene material used in PE bags provides varying levels of barrier properties against moisture, oxygen, and other gasses. This is an important feature for packaging sensitive products that need protection from external factors.

Advantages of Polyethylene (PE) Plastic Bags

PE plastic bags offer a compelling combination of advantages that have made them indispensable in various sectors. These benefits include:

- Cost-effectiveness: PE is a relatively inexpensive material, resulting in affordable PE bags. Their low cost makes them an economically viable packaging option for numerous applications.

- Ease of Handling: PE bags are lightweight and easy to handle, facilitating efficient packaging and transport. Their flexible nature allows them to be conveniently folded and stored when not in use.

- Versatility: PE bags are available in a diverse range of sizes, thicknesses, and colors, accommodating various packaging needs. They can be customized with printing, offering a branding opportunity for businesses.

- Recyclability: PE is a recyclable material, contributing to environmental sustainability. Many regions have systems for collecting and recycling PE bags, minimizing waste.

Applications of Polyethylene (PE) Plastic Bags

PE plastic bags have found application in numerous industries, owing to their versatile properties and cost-effectiveness. Some key applications include:

- Food Packaging: PE bags are extensively used to package food items, including fruits, vegetables, meat, poultry, and frozen foods. Their barrier properties protect food from contamination and spoilage.

- Industrial Applications: PE bags are used to package industrial components, chemicals, and other materials requiring containment and protection. They can be customized with specific barrier properties for specific applications.

- Retail Packaging: PE bags are used for packaging various retail products, including clothing, household items, and electronics. Their flexibility and transparency make them suitable for displaying goods.

- Agricultural Packaging: PE bags are employed in agriculture for storing and transporting seeds, fertilizers, and other agricultural inputs.

- Medical Applications: PE bags are utilized in healthcare for packaging sterile medical supplies, gloves, and other items.

Types of PE Plastic Bags

PE plastic bags are manufactured in various configurations to meet diverse requirements. Key variations include:

Thickness

- Thin Gauge: These bags are typically used for lightweight products, such as bread or vegetables.

- Medium Gauge: Medium-gauge bags are suitable for packaging heavier items, like fruits or groceries.

- Heavy Gauge: Heavy-duty bags are designed to carry substantial loads, such as construction materials or industrial supplies.

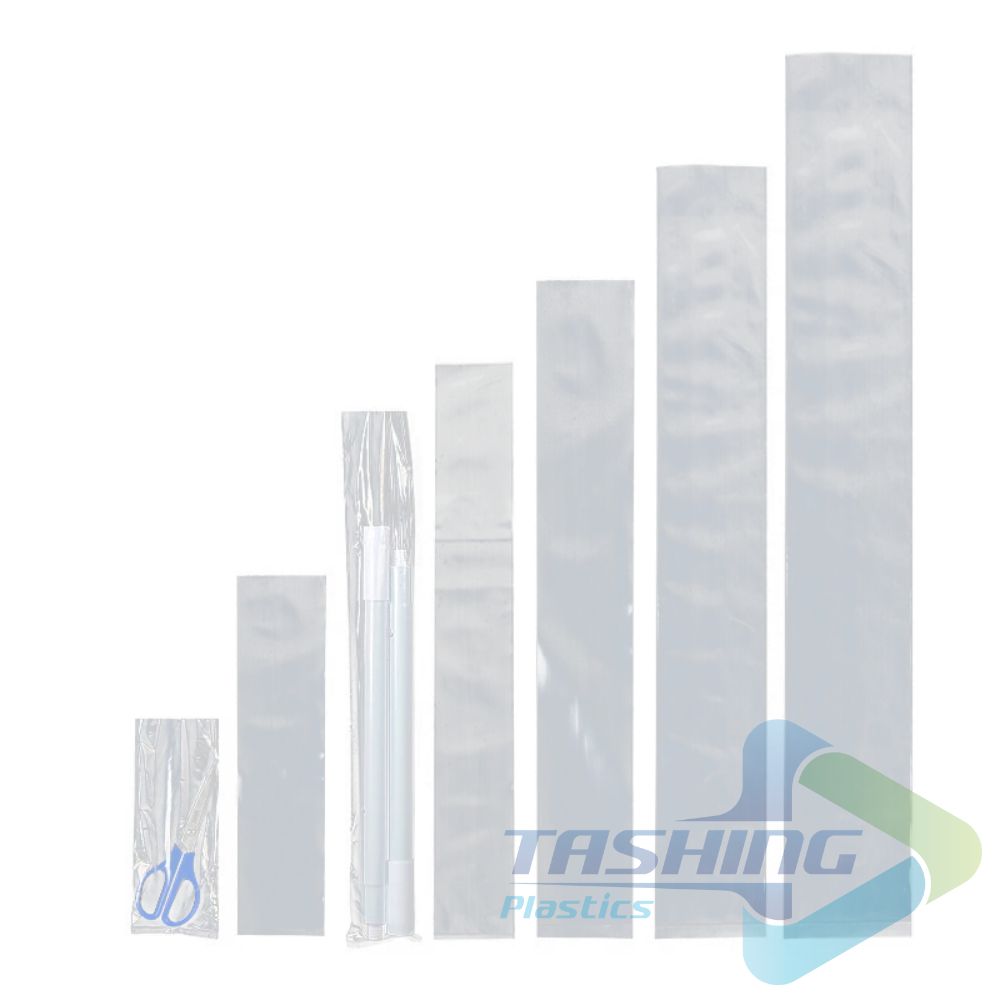

Size

PE bags come in various sizes, ranging from small, single-serving bags to large, industrial-scale bags. The appropriate size depends on the item being packaged.

Style

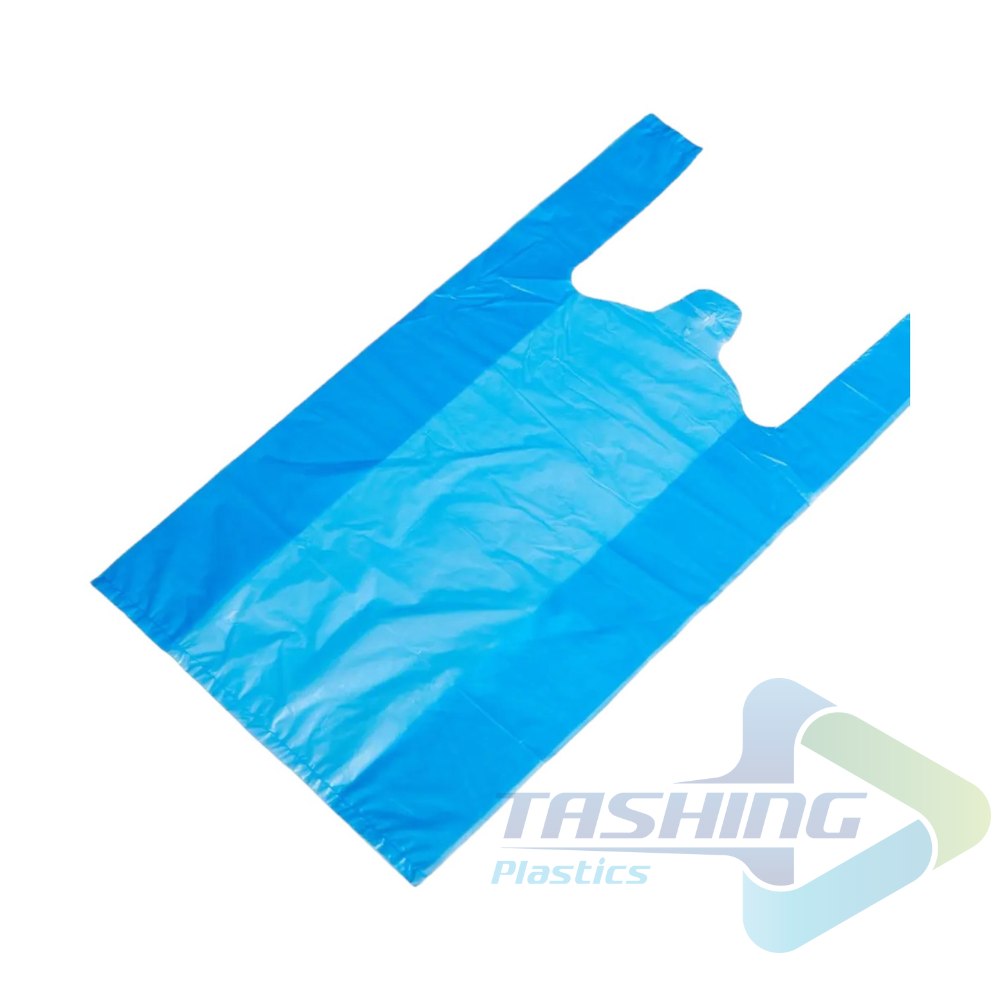

- T-Shirt Bags: These bags have two handle holes on the top and are commonly found in retail settings.

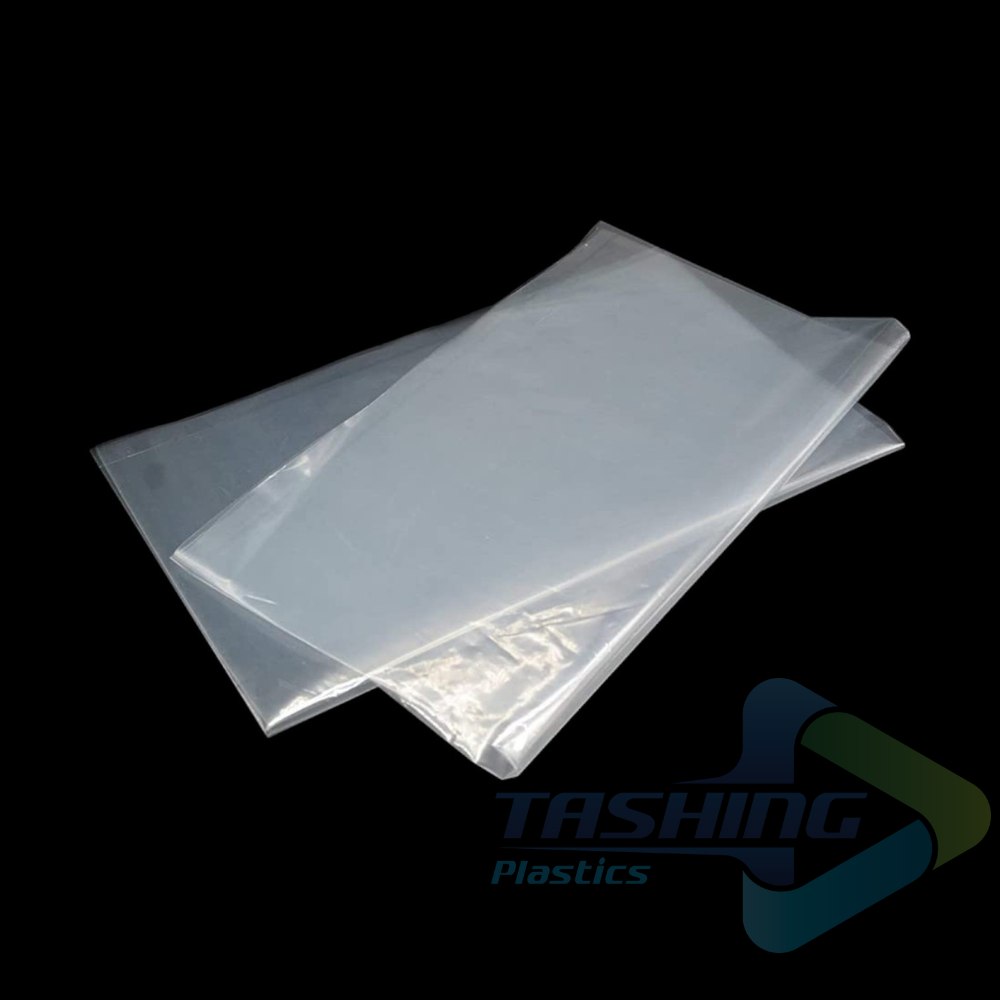

- Flat Bags: Flat bags are relatively thin and have a bottom gusset that can be expanded for added capacity. They are used for packaging items like bread or frozen foods.

- Stand Up Pouches: Stand-up pouches, with gussets on the sides and a bottom, can stand upright and are often used for packaging snacks, pet food, or other retail items.

- Ziplock Bags: Ziplock bags feature a resealable closure, offering convenient storage and freshness preservation.

Material

PE plastic bags can be manufactured from different types of polyethylene, each offering specific properties:

- Low-Density Polyethylene (LDPE): Known for its flexibility and toughness, LDPE is often used for general-purpose bags and packaging for food items.

- High-Density Polyethylene (HDPE): HDPE is a more rigid type of polyethylene, making it suitable for packaging heavier items or products that require greater stability.

Transparent PE Bags

What Are Transparent PE Bags?

Transparent PE bags are made from clear polyethylene film, allowing for easy visibility of the packaged products. This type of bag is particularly popular for retail applications and food packaging. Their clarity enhances product presentation and allows consumers to readily identify the contents.

Advantages of Transparent PE Bags

- Product Visibility: The transparency of the bag allows customers to see the product inside, enhancing the appeal and encouraging sales.

- Brand Visibility: Printed logos and designs on transparent PE bags are easily visible, promoting brand awareness and product recognition.

- Quality Assessment: Transparent bags allow customers to examine the product’s quality and condition before making a purchase.

Applications of Transparent PE Bags

- Retail Packaging: Transparent bags are widely used for packaging apparel, cosmetics, groceries, and other retail products. Their transparency helps to showcase the items effectively.

- Food Packaging: Transparent PE bags are frequently used to package fruits, vegetables, snacks, and other food items. They provide visibility and allow for easy inspection.

|  |  |

|  |  |

The Manufacturing Process of PE Bags

The process of manufacturing PE bags involves several steps, starting from the raw materials to the finished product.

Step 1: Material Preparation

The manufacturing process begins with selecting the appropriate type of polyethylene resin based on the intended application. The resin is then granulated and processed to ensure uniformity and quality.

Step 2: PE Melting

The polyethylene granules are melted in a carefully controlled process to form a molten plastic mixture. The melting temperature varies depending on the type of polyethylene used.

Step 3: Film Extrusion

The molten polyethylene is extruded through a die, forming a continuous film of desired thickness. This film serves as the base material for the PE bag.

Step 4: Film Winding or Cutting

The extruded film is either wound into rolls or cut into specific dimensions for subsequent bag making.

Step 5: Printing (if applicable)

If the PE bags require printing for branding or product information, the film is printed with the desired designs and text.

Step 6: Bag Fabrication

The printed film or plain film is then fed into bag-making machinery. The machinery sews, heat seals, or cuts the film to produce the specific type of PE bag desired.

Step 7: Quality Inspection

The finished PE bags undergo a quality inspection to ensure they meet specifications and are free from defects.

PE Plastic Bags in Ho Chi Minh City

Demand for PE Bags in Ho Chi Minh City

Ho Chi Minh City, a major economic hub in Vietnam, has a robust demand for PE plastic bags. The city’s diverse industries, retail sector, and growing consumption patterns contribute to high demand for this versatile packaging material.

Market for PE Bags in Ho Chi Minh City

The PE bag market in Ho Chi Minh City is bustling with manufacturers, suppliers, and retailers. The market offers a wide range of PE bags in various sizes, thicknesses, and styles to cater to diverse packaging requirements. The city’s strategically located manufacturing facilities also enable cost-effective production and distribution of PE bags.

Di Dai Hung Co., Ltd: A Leading PE Bag Manufacturer in Ho Chi Minh City

Introduction

Di Dai Hung Co., Ltd is a prominent manufacturer and supplier of PE plastic bags in Ho Chi Minh City. The company has gained a reputation for providing high-quality products and customer-centric services. Their commitment to innovation and sustainability has earned them recognition as a major player on Vietnam’s packaging landscape.

Products and Services

Di Dai Hung Co., Ltd offers a comprehensive range of PE plastic bags, including:

- T-shirt bags: Used for retail packaging, groceries, and other general purposes.

- Flat bags: Suitable for packaging frozen foods, bread, and other items.

- Stand up pouches: Designed for snacks, pet food, and other retail products.

- Ziplock bags: Useful for storing food and other items requiring resealable closure.

- Custom-designed bags: Di Dai Hung Co., Ltd provides custom-designed bags to meet specific client requirements.

Advantages of Choosing Di Dai Hung Co., Ltd

- High-quality products: Di Dai Hung Co., Ltd emphasizes quality control, ensuring that their bags meet industry standards and customer expectations.

- Competitive pricing: Di Dai Hung Co., Ltd offers competitive pricing, making their products accessible to a wide range of businesses.

- Fast turnaround time: The company prioritizes efficient operations, ensuring prompt delivery of orders to meet customer deadlines.

- Excellent customer support: Di Dai Hung Co., Ltd provides personalized support and guidance to assist customers in finding the optimal solutions for their packaging needs.

Conclusion

PE plastic bags continue to play a pivotal role in packaging a wide array of products across numerous industries. Their properties, advantages, and versatility make them an essential material in modern manufacturing and retail operations. Despite concerns surrounding plastic waste, the advancements in recyclable polyethylene materials and the growing emphasis on sustainable manufacturing practices offer a path toward responsible use of PE bags. As a prominent player in Ho Chi Minh City’s vibrant PE bag market, Di Dai Hung Co., Ltd exemplifies the manufacturing capabilities and commitment to quality that drives this thriving industry. The future of PE bags is likely to involve further innovation, technological advancements, and a focus on environmental sustainability, solidifying their position as a crucial element in the world of packaging.